Domestic Hot Water Service Systems - Design Procedures

Design procedures for domestic hot water service systems.

The design of a hot water service system may follow the procedure:

- Determine the demand of hot water from the consumers - quantity and temperature

- Select the type, capacity and heating surface of the calorifier - or heat exchanger

- Select the boiler

- Design the pipe scheme and the size of the pipes

The Demand of Hot Water - quantity and temperature

Hot water is normally supplied to fittings and their consumers at 50 - 60 oC. For canteens and professional kitchen temperatures of 65 oC are often required to satisfy hygienic standards. Hot water should not be stored at temperatures below 60 oC (140 oF) to avoid the risk of legionella contamination.

Where lower temperatures are necessary for safety reasons - as in kindergartens, centers for disabled etc. - the hot water temperature should not exceed 40 - 50 oC. Special care should be taken - like regular disinfection of fittings - to avoid legionalla infections.

Note! Hot water can be stored at higher temperatures and reduced to lower supply temperatures by mixing in cold water in blender valves. Storing the hot water at a higher temperatures increases the system overall capacity and reduces the need of storage volume.

Hot-Water Temperatures

| Consumer | Temperature (oC) |

|---|---|

| Showers | 43 |

| Lavatory - hand washing | 40 |

| Lavatory - shaving | 45 |

| Tubs | 43 |

| Therapeutic baths | 35 |

| Laundry, commercial | up to 82 |

Some typical water heater configurations:

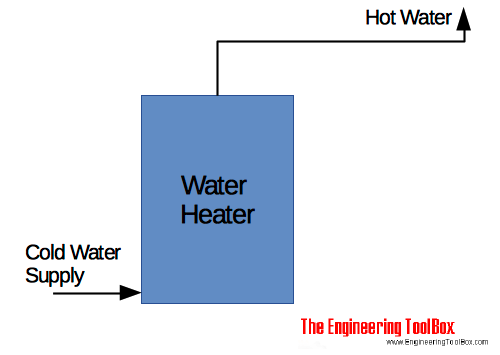

Water Heater - Single Temperature

The water is heated and stored in the same storage tank at the same temperature as supplied to the consumers.

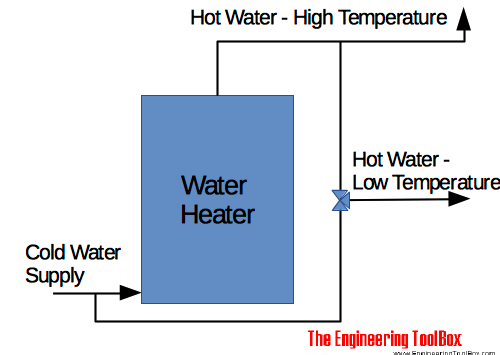

Water Heater - Two Temperature with Mixing Valve

The water is heated and stored in the same storage tank at higher temperature than supplied to most of the consumers. The hot water is mixed down to consumer temperature with cold water before supplied to the fittings.

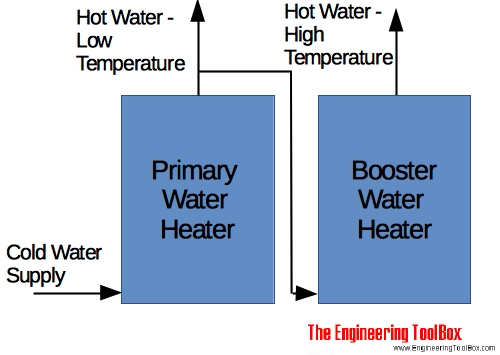

Water Heater - Two Temperature with Boosting Tank

The water is heated and stored at consumer temperature before distributed to normal consumers. Water from this store is supplied to an other heater and storage tank where the water is heated to higher temperatures before distribution.

The quantity of hot water is determined by number of occupants and their consumption habits. Timing is very important since consumption varies over the day.

Maximum Heat Supply

A hot water accumulator - tank volume - will reduce required maximum heat supply. The heat supply to a system with an accumulator can be calculated as:

H = cp V (q2 - q1) / t (1)

where

H = heat (power) supply (kW)

V = accumulator volume stored (liter)

cp = specific heat water (4.19 kJ/kgoC)

q1 = temperature of the cold feed water (oC)

q2 = temperature of the hot water (oC)

t = available time for the accumulated volume to be heated (sec)

Example - Required Power Supply to a Hot Water Accumulator

An accumulator with 200 liter is filled with cold water with temperature 5 oC. The electric power required to heat the water to 50 oC in 5.5 hours can be calculated as:

H = (4.19 kJ/kgoC) (200 liters) ((50 oC) - (5 oC)) / ((5.5 hours) (3600 s/hour))

= 1.9 kW

Which is close to the typical power of electric heating elements in hot water accumulators for normal consumption.

Accumulator Volume

Eq. (1) can be modified to express heated accumulated volume if heat supply capacity and available time for the heating is known:

V = Ha ta / (cp (q2 - q1)) (1b)

where

Ha = heat supply available (kW)

ta = heating time available (sec)

With an instantaneous heater with no accumulating calorifier - the heat supply can be calculated as:

H = cp v (q2 - q1) (2)

where

v = required volume flow (liter/s)

Example - Required Power to Continuously Heat Water

A shower consumes 0.05 liter/s of hot water. There is no storage tank and the water is heated continuously from 5 oC to 50 oC. Required power to heat the water can be calculated as

H = (4.19 kJ/kgoC) (0.05 liter/s) ((50 oC) - (5 oC))

= 9.4 kW

This high power demand is in general to much for common domestic electric systems and the main reason for the widely use of electric hot water accumulators.

A benefit with an accumulator is a stable hot water temperature. Modulating a large power supply may create unacceptable temperature variations - especially sensible in showers.

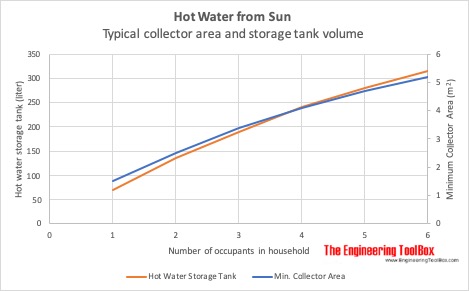

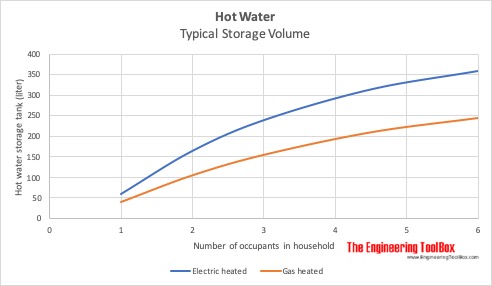

Typical Hot Water Storage Volume

Typical hot water storage volume for electric or gas heated systems vs. number of occupants in household:

Heating Surface

The required heating surface of an heat exchanger can be calculated as:

A = 1000 H / k qm (3)

where

A = heating surface (m2)

H = rate heating (kW)

k = overall heat transmission coefficient (W/m2K)

qm = logarithmic mean temperature difference (K)

The heat transmission coefficients depends on

- the materials used in the heat transmitting surfaces

- the construction of the heat exchanger - turbulent or not turbulent flow

- the type of fluids - their viscosities and specific heats

The Boiler

A boiler with correct rating must be selected from manufacturer catalogs where

Boiler rating = Heating capacity of calorifier + safety margin (normally 10 - 20%)

Design pipe scheme and size pipes

Maximum volume flow through connection pipes to fittings and other equipment is determined by the maximum demand of each consumer.

Maximum volume flow through main pipes is determined by the maximum demand of the fittings and statistic demand based on the number and types of fittings and equipment supplied.

Hot Water from Sun

The diagram below indicates typical minimum collector area and storage volume vs. occupants in a household for solar hot water production.