Centrifugal Pumps - Influence of Viscosity

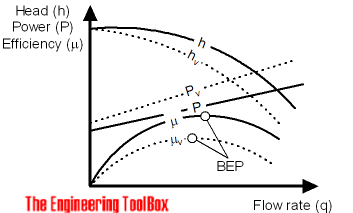

Hydrodynamic losses through pumps depends on fluid viscosities.

When a more viscous fluid is handled by a centrifugal pump

- brake horsepower requirement increases

- the head generated is reduced

- capacity is reduced

- efficiency of pump is reduced and the Best Efficiency Point - BEP - is moved

The head, flow and capacity with fluids with other viscosities than used in the original documentation can be modified with coefficients.

Flow

qv = cq q (1)

where

qv = flow compensated for viscosity (m3/h, gpm)

cq = viscosity flow coefficient

q = original flow according pump curve (m3/h, gpm)

Head

hv = ch h (2)

where

hv = head compensated for viscosity (m, ft)

ch = viscosity head coefficient

h = original head according pump curve (m, ft)

Efficiency

μv = cμ μ (3)

where

μv = effciency compensated for viscosity

cμ = viscosity efficiency coefficient

μ = original efficiency according pump curve

Power - SI units

Pv = qv hv ρv g / (3.6×106 μv) (4)

where

Pv = power compensated for viscosity (kW)

ρv = density of viscous fluid (kg/m3)

g = acceleration of gravity (9.81 m/s2)

Power - Imperial units

Pv = qv hv SG / (3960 μv) (5)

where

Pv = power compensated for viscosity (bhp)

SG = specific gravity of viscous fluid