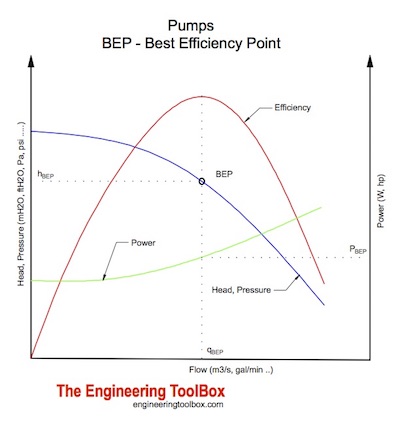

BEP - the Best Efficiency Point of a Pump

BEP is where the pump is most efficient.

A practical pump will never be able to convert all its kinetic energy to pressure energy. Parts of the energy will always be internal or external lost.

Internal Losses

- hydraulic loss - due to disk friction in the impeller, rapid change in flow directions and velocity changes throughout the pump

- volumetric loss - due to internal re-circulation caused by wear in rings and bushes

External Losses

- mechanical loss - due to friction in seals and bearings

BEP - Best Efficiency Point

The maximum efficiency for a pump is normally in its "design point" - also called

- BEP - or the "Best Efficiency Point"

For pumps operating in all other positions - the efficiency will be less than in BEP.