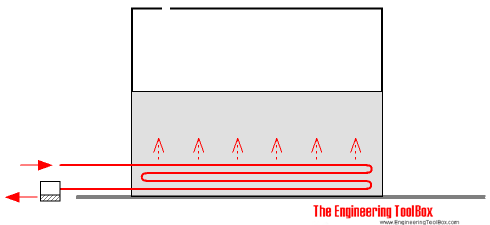

Pipes Submerged in Water - Heat Emission

Heat emision from steam or water heating pipes submerged in water - assisted (forced) or natural circulation.

Heat emission from steam or water pipes or tubes submerged in water:

| Temperature Difference between the Steam/Water in the Pipe and the Surrounding Water | Heat Transfer Rate to the Surrounding Water | ||

|---|---|---|---|

| (oF) | (oC) | (Btu/(ft2 h oF)) | (W/(m2 oC)) |

| 50 | 28 | 100 - 225 | 570 - 1280 |

| 100 | 56 | 175 - 300 | 1000 - 1700 |

| 200 | 111 | 225 - 475 | 1300 - 2700 |

Note that with a higher temperature difference there is a more vigorous movement on the water side and the heat transfer rate goes up. Forced or assisted circulation on the water side also results in higher heat transfer rates as indicated below.

For practical applications - the heat transfer rates can roughly be set to:

| Type of Application | Heat Transfer Rate to the Surrounding Water | |

|---|---|---|

| (Btu/(ft2 h oF)) | (W/(m2 oC)) | |

| Tank coils with low pressure steam, natural circulation in the tank | 100 | 570 |

| Tank coils with high pressure steam, natural circulation in the tank | 200 | 1100 |

| Tank coils with low pressure steam, forced circulation in the tank | 200 | 1100 |

| Tank coils with high pressure steam, forced circulation in the tank | 300 | 1700 |

- Dimensions of Carbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19

- Outside surface area - pipe equations

Example - Steam Coil in Water

A DN25 (1") Std steam coil of one meter is submerged in water with temperature 20 oC. The steam pressure is aprox. 1 bar with a steam temperature aprox. 120 oC.

The area of the submerged coil can be calculated as:

A = (1 m) 2 π (0.0334 m) / 2

= 0.10 m2

With low pressure steam and non-assisted circulation we presume from the table above that the heat transfer rate is 570 W/m2oC.

Heat transfer from steam to water can then be calculated:

Q = (570 W/(m2oC)) (0.10 m2) (120 oC - 20 oC)

= 5700 W

= 5.7 kW