Pipes Submerged in Oil or Fat - Heat Emission

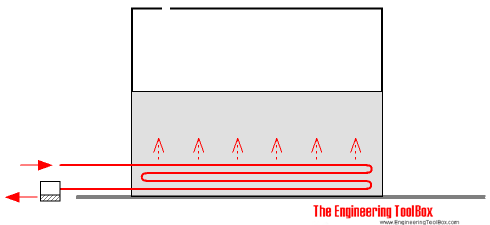

Heat emission from steam or water heating pipes submerged in oil or fat - forced and natural circulation.

The viscosity of a fluid has considerable influence on the heat transfered from a submerged heating pipe. Be aware that the viscosity of a fluid is highly dependent on the temperature.

Heat emission from steam pipes submerged in oil baths are indicated below:

| Application | Fluid | Heat Emission from coil surface | |

|---|---|---|---|

| (Btu/ft2 hr oF) | (W/m2 oC) | ||

| Steam coil with medium steam pressure and natural convection of oil | Light Oils | 30 | 170 |

| Heavy Oils | 15 - 20 | 85 - 115 | |

| Fats | 5 - 10 | 30 - 60 | |

| Steam coil with medium pressure and forced convection of oil | Light Oils | 100 | 570 |

| Heavy Oils | 60 | 340 | |

| Fats | 30 | 170 | |

- Light oils - 220 SSU at 100 oF

- Heavy oils - 1100 SSU at 100 oF

- Fats - 3833 SSU at 100 oF

- Carbon, Alloy and Stainless Steel Pipes - ASME/ANSI B36.10/19 - dimensions

- Outside surface area - pipe equations

Example - Heat Emission from a 2" Coil in a Fat Tank

A 10 m long 2" inch stainless steel steam coil heats a tank with fat. The steam pressure is 1 bar and the temperature in the coil is 120 oC. The temperature in the tank is 40 oC. The convection is natural with heat emission 50 W/m2oC.

The outside diameter of the pipe is 60.3 mm and the external surface of the pipe pr. m length of pipe can be calculated as

As = 2 π ((0.063 m) / 2) (1 m)

= 0.2 m2/m pipe

The heat emission from the coil as whole can be calculated as

Q = (10 m) (0.2 m2/m pipe) (50 W/m2oC) ((120 oC) - (40 oC))

= 8000 W

= 8 kW