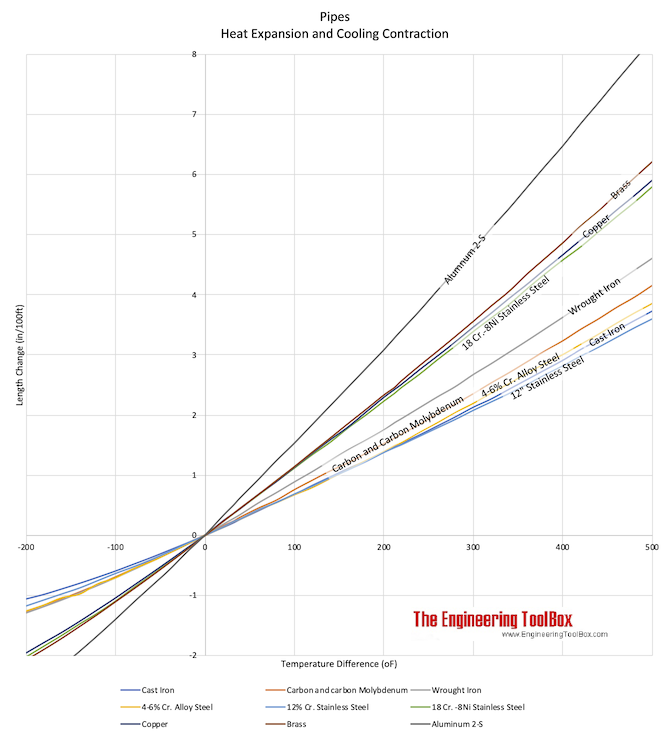

Piping Materials - Temperature Heat Expansion and Cooling Contraction

Expansion and contraction when cast iron, carbon and carbon molybdenum steel, wrought iron, copper, brass and aluminum pipes are heated or cooled.

Temperature expansion of pipes or tubes with some commonly used materials:

For full table with wrought iron, stainless steel, copper, brass and aluminum - rotate the screen!

| Saturated Steam Pressure1) (psi) | Temperature (oF) | Temperature Expansion of Pipes (in/100 ft) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cast Iron | Carbon and carbon Molybdenum | Wrought Iron | 4-6% Cr. Alloy Steel | 12% Cr. Stainless Steel | 18 Cr. -8Ni Stainless Steel | Copper | Brass | Aluminum 2-S | ||

| -200 | -1.058 | -1.282 | -1.289 | -1.250 | -1.170 | -2.030 | -1.955 | -2.065 | -2.69 | |

| -180 | -0.982 | -1.176 | -1.183 | -1.150 | -1.070 | -1.850 | -1.782 | -1.890 | -2.44 | |

| -160 | -0.891 | -1.066 | -1.073 | -1.030 | -0.970 | -1.670 | -1.612 | -1.705 | -2.18 | |

| -140 | -0.797 | -0.948 | -0.955 | -0.970 | -0.870 | -1.480 | -1.428 | -1.508 | -1.93 | |

| -120 | -0.697 | -0.826 | -0.833 | -0.800 | -0.750 | -1.300 | -1.235 | -1.308 | -1.67 | |

| -100 | -0.593 | -0.698 | -0.705 | -0.700 | -0.630 | -1.100 | -1.040 | -1.098 | -1.40 | |

| -80 | -0.481 | -0.563 | -0.570 | -0.550 | -0.520 | -0.880 | -0.835 | -0.888 | -1.12 | |

| -60 | -0.368 | -0.428 | -0.435 | -0.430 | -0.400 | -0.670 | -0.630 | -0.673 | -0.85 | |

| -40 | -0.248 | -0.288 | -0.295 | -0.290 | -0.270 | -0.450 | -0.421 | -0.452 | -0.58 | |

| -20 | -0.127 | -0.145 | -0.152 | -0.145 | -0.130 | -0.225 | -0.210 | -0.227 | -0.28 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 20 | 0.128 | 0.148 | 0.180 | 0.140 | 0.140 | 0.223 | 0.238 | 0.233 | 0.32 | |

| 32 | 0.209 | 0.230 | 0.280 | 0.234 | 0.234 | 0.356 | 0.366 | 0.373 | 0.50 | |

| 29.39 | 40 | 0.270 | 0.300 | 0.350 | 0.280 | 0.280 | 0.446 | 0.451 | 0.466 | 0.63 |

| 60 | 0.410 | 0.448 | 0.540 | 0.430 | 0.430 | 0.669 | 0.684 | 0.690 | 0.93 | |

| 28.89 | 80 | 0.550 | 0.580 | 0.710 | 0.600 | 0.580 | 0.892 | 0.896 | 0.920 | 1.24 |

| 27.99 | 100 | 0.680 | 0.753 | 0.887 | 0.650 | 0.690 | 1.115 | 1.134 | 1.150 | 1.53 |

| 26.48 | 120 | 0.830 | 0.910 | 1.058 | 0.800 | 0.820 | 1.338 | 1.366 | 1.390 | 1.84 |

| 24.04 | 140 | 0.970 | 1.064 | 1.240 | 0.950 | 0.960 | 1.545 | 1.590 | 1.625 | 2.15 |

| 20.27 | 160 | 1.110 | 1.200 | 1.420 | 1.100 | 1.090 | 1.784 | 1.804 | 1.865 | 2.46 |

| 14.63 | 180 | 1.240 | 1.360 | 1.580 | 1.250 | 1.230 | 2.000 | 2.051 | 2.100 | 2.77 |

| 6.45 | 200 | 1.390 | 1.520 | 1.750 | 1.400 | 1.380 | 2.230 | 2.296 | 2.340 | 3.08 |

| 0 | 212 | 1.480 | 1.610 | 1.870 | 1.500 | 1.460 | 2.361 | 2.428 | 2.467 | 3.28 |

| 2.5 | 220 | 1.530 | 1.680 | 1.940 | 1.550 | 1.510 | 2.460 | 2.516 | 2.580 | 3.41 |

| 10.3 | 240 | 1.670 | 1.840 | 2.120 | 1.720 | 1.650 | 2.680 | 2.756 | 2.830 | 3.73 |

| 20.7 | 260 | 1.820 | 2.020 | 2.300 | 1.880 | 1.790 | 2.920 | 2.985 | 3.070 | 4.07 |

| 34.5 | 280 | 1.970 | 2.180 | 2.470 | 2.050 | 1.930 | 3.150 | 3.218 | 3.315 | 4.40 |

| 52.3 | 300 | 2.130 | 2.350 | 2.670 | 2.200 | 2.080 | 3.390 | 3.461 | 3.565 | 4.74 |

| 74.9 | 320 | 2.268 | 2.530 | 2.850 | 2.370 | 2.220 | 3.615 | 3.696 | 3.820 | 5.10 |

| 103.3 | 340 | 2.430 | 2.700 | 3.040 | 2.530 | 2.360 | 3.840 | 3.941 | 4.065 | 5.43 |

| 138.3 | 360 | 2.590 | 2.880 | 3.230 | 2.700 | 2.510 | 4.100 | 4.176 | 4.350 | 5.78 |

| 180.9 | 380 | 2.750 | 3.060 | 3.425 | 2.860 | 2.670 | 4.346 | 4.424 | 4.610 | 6.13 |

| 232.4 | 400 | 2.910 | 3.230 | 3.620 | 3.010 | 2.820 | 4.580 | 4.666 | 4.870 | 6.47 |

| 293.7 | 420 | 3.090 | 3.421 | 3.820 | 3.180 | 2.980 | 4.800 | 4.914 | 5.150 | 6.84 |

| 366.1 | 440 | 3.250 | 3.595 | 4.020 | 3.350 | 3.130 | 5.050 | 5.154 | 5.400 | 7.19 |

| 451.3 | 460 | 3.410 | 3.784 | 4.200 | 3.530 | 3.290 | 5.300 | 5.408 | 5.680 | 7.55 |

| 550.3 | 480 | 3.570 | 3.955 | 4.400 | 3.700 | 3.450 | 5.540 | 5.651 | 5.950 | 7.90 |

| 664.3 | 500 | 3.730 | 4.151 | 4.600 | 3.860 | 3.600 | 5.800 | 5.906 | 6.220 | 8.25 |

| 795.3 | 520 | 3.900 | 4.342 | 4.810 | 4.040 | 3.760 | 6.050 | 6.148 | 6.500 | 8.61 |

| 945.3 | 540 | 4.080 | 4.525 | 5.020 | 4.200 | 3.930 | 6.280 | 6.410 | 6.780 | 8.98 |

1) Vacuum in degree below 211 oF, psi gauge above 211 oF

- T (oC) = 5/9 (T (oF) - 32)

- 1 in (inch) = 25.4 mm

- 1 ft (foot) = 0.3048 m