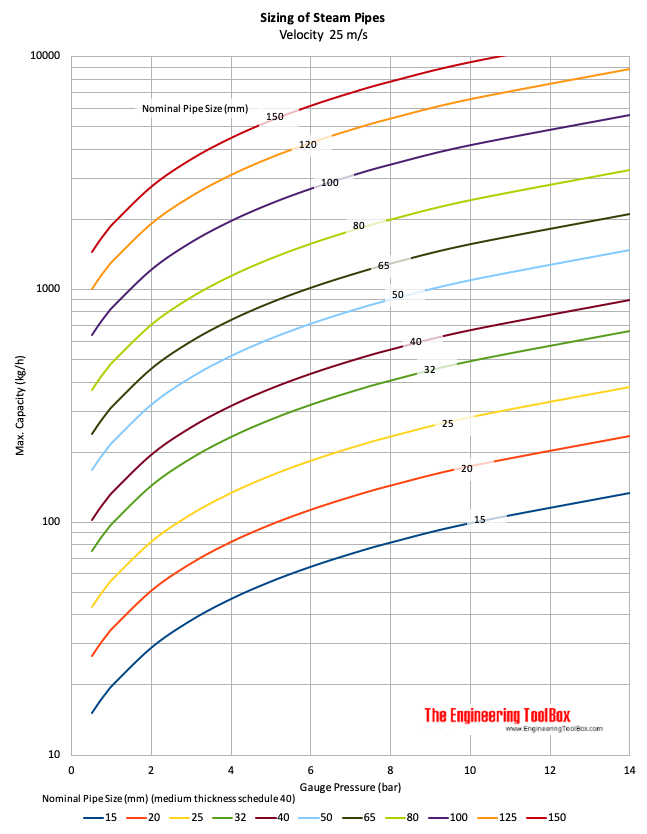

Sizing Steam Pipes (kg/h)

Steam is a compressible gas where pipe line mass flow capacity depends on steam pressure.

Steam is a compressible gas where mass flow capacity of pipe lines depends on steam pressures. Steam pipes can be sized with the table and diagram below - pressure in bar, velocity in m/s and capacity in kg/h.

Steam velocities of 25 m/s are in general sufficient for most saturated steam applications.

For full table with larger dimensions - rotate the screen!

| Capacity (kg/h) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gauge Pressure (bar) | Steam Velocity (m/s) | Nominal Pipe Size (mm) | ||||||||||

| 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | ||

| Innside Diameter (mm) | ||||||||||||

| 15.8 | 20.9 | 26.6 | 35.0 | 40.9 | 52.5 | 62.7 | 77.9 | 102.3 | 128.2 | 154.1 | ||

| 0.4 | 15 | 9 | 15 | 24 | 42 | 57 | 95 | 135 | 208 | 359 | 564 | 815 |

| 25 | 14 | 25 | 41 | 70 | 96 | 158 | 225 | 347 | 598 | 940 | 1358 | |

| 40 | 23 | 40 | 65 | 112 | 153 | 252 | 360 | 555 | 958 | 1504 | 2173 | |

| 0.5 | 15 | 9 | 16 | 26 | 45 | 61 | 101 | 144 | 222 | 383 | 602 | 869 |

| 25 | 15 | 27 | 43 | 75 | 102 | 168 | 240 | 370 | 638 | 1003 | 1449 | |

| 40 | 24 | 43 | 69 | 120 | 163 | 269 | 384 | 592 | 1021 | 1604 | 2318 | |

| 0.7 | 15 | 10 | 18 | 29 | 51 | 69 | 113 | 162 | 250 | 431 | 676 | 977 |

| 25 | 17 | 30 | 49 | 84 | 115 | 189 | 270 | 416 | 718 | 1127 | 1628 | |

| 40 | 27 | 48 | 78 | 135 | 184 | 302 | 431 | 666 | 1148 | 1803 | 2605 | |

| 0.9 | 15 | 11 | 20 | 32 | 56 | 76 | 126 | 179 | 277 | 478 | 750 | 1084 |

| 25 | 19 | 33 | 54 | 93 | 127 | 210 | 299 | 462 | 796 | 1250 | 1806 | |

| 40 | 30 | 53 | 86 | 149 | 204 | 335 | 478 | 738 | 1274 | 2000 | 2890 | |

| 1 | 15 | 12 | 21 | 34 | 59 | 80 | 132 | 188 | 291 | 501 | 787 | 1137 |

| 25 | 20 | 35 | 57 | 98 | 133 | 220 | 314 | 484 | 835 | 1312 | 1895 | |

| 40 | 32 | 56 | 91 | 157 | 214 | 352 | 502 | 775 | 1336 | 2099 | 3032 | |

| 2 | 15 | 17 | 31 | 50 | 86 | 117 | 193 | 275 | 425 | 733 | 1151 | 1663 |

| 25 | 29 | 51 | 83 | 143 | 195 | 322 | 459 | 708 | 1221 | 1918 | 2771 | |

| 40 | 47 | 82 | 133 | 229 | 312 | 515 | 734 | 1133 | 1954 | 3069 | 4434 | |

| 3 | 15 | 23 | 40 | 65 | 113 | 153 | 253 | 361 | 557 | 960 | 1508 | 2178 |

| 25 | 38 | 67 | 109 | 188 | 256 | 421 | 601 | 928 | 1600 | 2513 | 3631 | |

| 40 | 61 | 107 | 174 | 300 | 409 | 674 | 962 | 1485 | 2560 | 4021 | 5809 | |

| 4 | 15 | 28 | 50 | 80 | 139 | 189 | 312 | 445 | 687 | 1185 | 1860 | 2688 |

| 25 | 47 | 83 | 134 | 232 | 316 | 520 | 742 | 1145 | 1974 | 3101 | 4480 | |

| 40 | 75 | 132 | 214 | 371 | 505 | 832 | 1187 | 1832 | 3159 | 4961 | 7168 | |

| 5 | 15 | 34 | 59 | 95 | 165 | 225 | 371 | 529 | 816 | 1407 | 2210 | 3193 |

| 25 | 56 | 98 | 159 | 275 | 375 | 618 | 881 | 1360 | 2345 | 3683 | 5321 | |

| 40 | 90 | 157 | 254 | 440 | 600 | 988 | 1409 | 2176 | 3752 | 5892 | 8514 | |

| 6 | 15 | 39 | 68 | 110 | 191 | 260 | 429 | 611 | 944 | 1628 | 2556 | 3693 |

| 25 | 65 | 114 | 184 | 318 | 434 | 714 | 1019 | 1573 | 2713 | 4260 | 6155 | |

| 40 | 104 | 182 | 294 | 509 | 694 | 1143 | 1630 | 2517 | 4340 | 6816 | 9848 | |

| 7 | 15 | 44 | 77 | 125 | 217 | 295 | 487 | 694 | 1071 | 1847 | 2901 | 4192 |

| 25 | 73 | 129 | 209 | 361 | 492 | 811 | 1157 | 1785 | 3079 | 4835 | 6986 | |

| 40 | 118 | 206 | 334 | 578 | 787 | 1297 | 1851 | 2856 | 4926 | 7736 | 11178 | |

| 8 | 15 | 49 | 86 | 140 | 242 | 330 | 544 | 776 | 1198 | 2066 | 3245 | 4688 |

| 25 | 82 | 144 | 234 | 404 | 550 | 907 | 1294 | 1997 | 3444 | 5408 | 7814 | |

| 40 | 131 | 231 | 374 | 646 | 881 | 1451 | 2070 | 3195 | 5510 | 8653 | 12502 | |

| 10 | 15 | 60 | 105 | 170 | 294 | 400 | 659 | 940 | 1451 | 2502 | 3930 | 5678 |

| 25 | 99 | 175 | 283 | 489 | 667 | 1098 | 1567 | 2418 | 4171 | 6550 | 9464 | |

| 40 | 159 | 279 | 453 | 783 | 1067 | 1758 | 2507 | 3869 | 6673 | 10480 | 15142 | |

| 14 | 15 | 80 | 141 | 229 | 396 | 539 | 888 | 1266 | 1955 | 3371 | 5295 | 7650 |

| 25 | 134 | 235 | 381 | 659 | 898 | 1480 | 2111 | 3258 | 5619 | 8825 | 12750 | |

| 40 | 214 | 376 | 610 | 1055 | 1437 | 2368 | 3377 | 5213 | 8991 | 14119 | 20401 | |

The values above are calculated for steel pipes medium thickness schedule 40. Using other standards with different inside diameters, the values above should be compensated.

Example - Capacity of 50 mm Steam Pipe

The capacity of a 50 mm steam pipe with 10 bar pressure and steam velocity 25 m/s is 1098 kg/h.

Related Topics

-

Sizing of Steam and Condensate Pipes

Dimensions of steam and condensate pipe lines. Calculate pressure losses, recommended velocities, capacities and more. -

Steam and Condensate

Design of steam & condensate systems with properties, capacities, sizing of pipe lines, system configuration and more.

Related Documents

-

ANSI Schedule 40 Steel Pipes - Dimensions

Internal and external diameters, areas, weights, volumes and number of threads for ANSI schedule 40 steel pipes. -

EN 10255 - Non-alloy Steel Tubes for Welding and Threading - Dimensions

Dimensions and weights of steel tubes according BS EN 10255. -

Piping Materials - Temperature Heat Expansion and Cooling Contraction

Expansion and contraction when cast iron, carbon and carbon molybdenum steel, wrought iron, copper, brass and aluminum pipes are heated or cooled. -

Properties of Saturated Steam - SI Units

Saturated Steam Table with steam properties as specific volume, density, specific enthalpy and specific entropy. -

Recommended Velocities in Steam Systems

The steam velocity in a steam distribution system should be within certain limits to avoid excessive wear and tear -

Sizing Steam Pipes (lb/h)

Steam is a compressible gas where the capacity of a pipe line depends on the size of the pipe and the steam pressure. -

Steam & Condensate Equations

Steam consumption and condensate generation when heating liquid or gas flows -

Steam - Flow vs. kW Rating

Calculate steam flow rate vs. kW rating. -

Steam Consumption for some Typical Steam Heated Consumers

Steam consumption rates for typical steam heated consumers in industries like bakeries, breweries, paper factories etc. -

Steam Flow Rate vs. Pressure Drop - Schedule 40 Pipe

Flow rate (lb/h) and pressure drop per 100 feet of pipe. -

Steam Heating Processes - Load Calculating

Calculating the amount of steam in non-flow batch and continuous flow heating processes. -

Steam Pipes - Max. Flow and Pressure Drop

Pressure drop and maximum allowable flow in steam pipes. -

Steam Pipes - Online Pressure drop Calculator

Calculate pressure drops in steam distribution pipe lines. -

Steam Pipes - Pressure Drop vs. Steam Flow

Steam pipes and pressure drop diagrams - imperial and metric units. -

Steam Pipes - Sizing

Sizing of steam pipe lines - major and minor loss in steam distribution systems. -

Steam Pipes - Thermal Expansion

Thermal expansion of steam pipes heated from room temperature to operation temperature (mm pr. 100 m pipe). -

Thermal Expansion of Steam Pipes - (inches)

Expansion of steam pipes heated from room temperature to operation temperature.