Ethylene Glycol Heat-Transfer Fluid Properties: Density, Data & Charts

Properties like freezing point, viscosity, specific gravity and specific heat of ethylene glycol based heat-transfer fluids, or brines.

Ethylene Glycol based water solutions are common in heat-transfer applications where the temperature in the heat transfer fluid can be below 32 oF (0 oC). Ethylene glycol is also commonly used in heating applications that temporarily may not be operated (cold) in surroundings with freezing conditions - such as cars and machines with water cooled engines.

Ethylene Glycol is the most common antifreeze fluid for standard heating and cooling applications. Ethylene glycol should be avoided if there is a slightest chance of leakage to potable water or food processing systems. Instead solutions based on propylene glycol are commonly used.

Specific heat, viscosity and specific weight of a water and ethylene glycol solution vary significantly with the percent of ethylene glycol and the temperature of the fluid. Properties differs so much from clean water that heat transfer systems with ethylene glycol should be calculated thoroughly for actual temperature and solution.

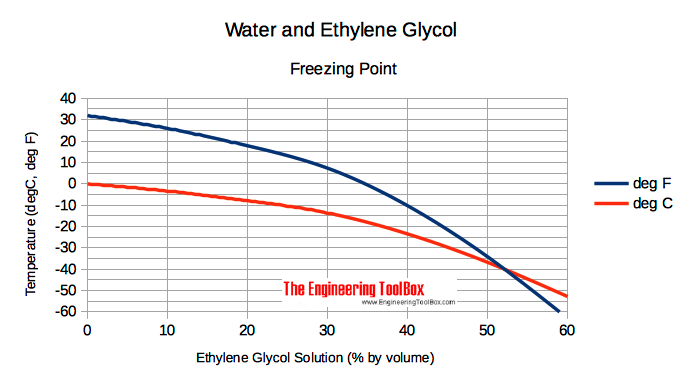

Freezing Point of Ethylene Glycol based Water Solutions

Freezing points of ethylene glycol based water solutions at various temperatures are indicated below

| Ethylene Glycol Solution (% by volume) | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 80 | 90 | 100 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Freezing Point | (oF) | 32 | 25.9 | 17.8 | 7.3 | -10.3 | -34.2 | -63 | ≈ -51 | ≈ -22 | 9 |

| (oC) | 0 | -3.4 | -7.9 | -13.7 | -23.5 | -36.8 | -52.8 | ≈ -46 | ≈ -30 | -12.8 | |

Due to possible slush creation, ethylene glycol and water solutions should not be used in conditions close to freezing points.

Dynamic Viscosity of Ethylene Glycol based Water Solutions

Dynamic viscosity - μ - of ethylene glycol based water solutions at various temperatures are indicated below

| Temperature | Dynamic Viscosity - μ - (centiPoise) | |||||||

|---|---|---|---|---|---|---|---|---|

| Ethylene Glycol Solution (% by volume) | ||||||||

| (oF) | (oC) | 25 | 30 | 40 | 50 | 60 | 65 | 100 |

| 0 | -17.8 | 1) | 1) | 15 | 22 | 35 | 45 | 310 |

| 40 | 4.4 | 3 | 3.5 | 4.8 | 6.5 | 9 | 10.2 | 48 |

| 80 | 26.7 | 1.5 | 1.7 | 2.2 | 2.8 | 3.8 | 4.5 | 15.5 |

| 120 | 48.9 | 0.9 | 1 | 1.3 | 1.5 | 2 | 2.4 | 7 |

| 160 | 71.1 | 0.65 | 0.7 | 0.8 | 0.95 | 1.3 | 1.5 | 3.8 |

| 200 | 93.3 | 0.48 | 0.5 | 0.6 | 0.7 | 0.88 | 0.98 | 2.4 |

| 240 | 115.6 | 2) | 2) | 2) | 2) | 2) | 2) | 1.8 |

| 280 | 137.8 | 2) | 2) | 2) | 2) | 2) | 2) | 1.2 |

- below freezing point

- above boiling point

Note! The dynamic viscosity of an ethylene glycol based water solution is increased compared with the dynamic viscosity of clean water . As a consequence the head loss (pressure loss) in the a piping system with ethylene glycol is increased compared to clean water.

Specific Gravity of Ethylene Glycol based Water Solutions

Specific gravity - SG - of ethylene glycol based water solutions at various temperatures are indicated below

| Temperature | Specific Gravity - SG - | |||||||

|---|---|---|---|---|---|---|---|---|

| Ethylene Glycol Solution (% by volume) | ||||||||

| (oF) | (oC) | 25 | 30 | 40 | 50 | 60 | 65 | 100 |

| -40 | -40 | 1) | 1) | 1) | 1) | 1.12 | 1.13 | 1) |

| 0 | -17.8 | 1) | 1) | 1.08 | 1.10 | 1.11 | 1.12 | 1.16 |

| 40 | 4.4 | 1.048 | 1.057 | 1.07 | 1.088 | 1.1 | 1.11 | 1.145 |

| 80 | 26.7 | 1.04 | 1.048 | 1.06 | 1.077 | 1.09 | 1.095 | 1.13 |

| 120 | 48.9 | 1.03 | 1.038 | 1.05 | 1.064 | 1.077 | 1.082 | 1.115 |

| 160 | 71.1 | 1.018 | 1.025 | 1.038 | 1.05 | 1.062 | 1.068 | 1.1 |

| 200 | 93.3 | 1.005 | 1.013 | 1.026 | 1.038 | 1.049 | 1.054 | 1.084 |

| 240 | 115.6 | 2) | 2) | 2) | 2) | 2) | 2) | 1.067 |

| 280 | 137.8 | 2) | 2) | 2) | 2) | 2) | 2) | 1.05 |

- below freezing point

- above boiling point

Note! The specific gravity of ethylene glycol based water solutions are increased compared with specific gravity of clean water.

Densities of Ethylene Glycol based Water Solutions

Turn the screen to see the whole table.

| Mass Fraction of Ethylene Glycol in Solution | Density - ρ - (kg/m3) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature - t - (oC) | ||||||||||||

| -48 | -35 | -25 | -14 | -8 | -4 | 0 | 20 | 40 | 60 | 80 | 100 | |

| 0 | 1000 | 998 | 992 | 983 | 972 | 958 | ||||||

| 0.1 | 1019 | 1018 | 1014 | 1008 | 1000 | 992 | 984 | |||||

| 0.2 | 1038 | 1037 | 1036 | 1030 | 1022 | 1014 | 1005 | 995 | ||||

| 0.3 | 1058 | 1056 | 1055 | 1054 | 1046 | 1037 | 1027 | 1017 | 1007 | |||

| 0.4 | 1080 | 1077 | 1075 | 1073 | 1072 | 1063 | 1052 | 1041 | 1030 | 1018 | ||

| 0.5 | 1103 | 1100 | 1096 | 1093 | 1092 | 1090 | 1079 | 1067 | 1055 | 1042 | 1030 | |

| 0.6 | 1127 | 1124 | 1120 | 1115 | 1112 | 1110 | 1107 | 1095 | 1082 | 1068 | 1055 | 1042 |

Example - Expansion Volume in a Heating System with Ethylene Glycol

A heating system with liquid volume 0.8 m3 is freeze protected with 50% (by mass, mass fraction 0.5) ethylene glycol. The installation temperature of the system is down to 0 oC and the maximum medium operation temperature is 80 oC .

From the table above we see that the density of the solution at installation temperature can be as high as 1090 kg/m3 - and the medium density at operation temperature can be as low as 1042 kg/m3 .

The mass of the liquid at installation can be calculated as

minst = ρinst Vinst (1)

= (1090 kg/m3) (0.8 m3)

= 872 kg

where

minst = mass of liquid at installation (kg)

ρinst = density at installation (kg/m3)

Vinst = liquid volume at installation (m3)

Mass of the liquid in the system during operation will be same as the mass in system during installation

minst = mop (2)

= ρop Vop

where

mop = mass of liquid at operation (kg)

ρop = density at operation (kg/m3)

Vop = liquid volume at operation (m3)

(2) can be modified to calculate liquid operation volume as

Vop = minst / ρop (2b)

= (872 kg) / ( 1042 kg/m3)

= 0.837 m3

The required expansion volume to avoid pressure can be calculated as

ΔV = Vop - Vinst (3)

= (0.837 m3) - (0.8 m3)

= 0.037 m3

= 37 liter

where

ΔV = expansion volume (m3)

Expansion volume can be calculated as

ΔV = ( ρinst / ρop - 1) Vinst (4)

Specific Heat of Ethylene Glycol based Water Solutions

Specific Heat - cp - of ethylene glycol based water solutions at various temperatures are indicated below

Turn the screen to the whole table.

| Ethylene Glycol Solution (% by weight) | Specific Heat - cp (Btu/lb oF) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | ||||||||||||||||

| -50 | -40 | -30 | -20 | -10 | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | |

| 0 | 1.0038 | 1.0018 | 1.0004 | 0.99943 | 0.99902 | 0.99913 | 0.99978 | 1.0009 | 1.0026 | 1.0049 | 1.0076 | |||||

| 10 | 0.97236 | 0.97422 | 0.97619 | 0.97827 | 0.98047 | 0.98279 | 0.98521 | 0.98776 | 0.99041 | 0.99318 | 0.99607 | |||||

| 20 | 0.93576 | 0.93976 | 0.94375 | 0.94775 | 0.95175 | 0.95574 | 0.95974 | 0.96373 | 0.96773 | 0.97173 | 0.97572 | |||||

| 30 | 0.89373 | 0.89889 | 0.90405 | 0.90920 | 0.91436 | 0.91951 | 0.92467 | 0.92982 | 0.93498 | 0.94013 | 0.94529 | 0.95044 | ||||

| 40 | 0.84605 | 0.85232 | 0.85858 | 0.86484 | 0.87111 | 0.87737 | 0.88364 | 0.88990 | 0.89616 | 0.90243 | 0.90869 | 0.91496 | 0.92122 | |||

| 50 | 0.79288 | 0.80021 | 0.80753 | 0.81485 | 0.82217 | 0.82949 | 0.83682 | 0.84414 | 0.85146 | 0.85878 | 0.86610 | 0.87343 | 0.88075 | 0.88807 | ||

| 60 | 0.72603 | 0.73436 | 0.74269 | 0.75102 | 0.75935 | 0.76768 | 0.77601 | 0.78434 | 0.79267 | 0.80100 | 0.80933 | 0.81766 | 0.82599 | 0.83431 | 0.84264 | 0.85097 |

| 70 | 0.67064 | 0.67992 | 0.68921 | 0.69850 | 0.70778 | 0.71707 | 0.72636 | 0.73564 | 0.74493 | 0.75422 | 0.76350 | 0.77279 | 0.78207 | 0.79136 | 0.80065 | 0.80993 |

| 80 | 0.61208 | 0.62227 | 0.63246 | 0.64265 | 0.65285 | 0.66304 | 0.67323 | 0.68343 | 0.69362 | 0.70381 | 0.71401 | 0.72420 | 0.73439 | 0.74458 | 0.75478 | 0.76497 |

| 90 | 0.58347 | 0.59452 | 0.60557 | 0.61662 | 0.62767 | 0.63872 | 0.64977 | 0.66082 | 0.67186 | 0.68291 | 0.69396 | 0.70501 | 0.71606 | |||

| 100 | 0.53282 | 0.54467 | 0.55652 | 0.56838 | 0.58023 | 0.59209 | 0.60394 | 0.61579 | 0.62765 | 0.63950 | 0.65136 | 0.66321 | ||||

- Freezing point 100% ethylene glycol at atmospheric pressure is -12.8 oC (9 oF)

- 1 Btu/lbmoF = 4,186.8 J/(kg K) = 1 kcal/(kg oC)

Note! The specific heat of ethylene glycol based water solutions are less than the specific heat of clean water. For a heat transfer system with ethylene glycol the circulated volume must be increased compared to a system only with water.

In a 50% solution with operational temperatures above 36 oF the specific heat capacity is decreased with approximately 20%. The reduced heat capacity must be compensated by circulating more fluid.

Note! The density of ethylene glycol is higher than water - check the specific gravity (SG) table above, so the net impact on the heat transport capacity is reduced. Example - the specific heat of an ethylene glycol water solution 50% / 50% is 0.815 at 80 oF (26.7 oC). Specific gravity at the same conditions is 1.077. The net impact can be estimated to 0.815 * 1.077 = 0.877.

Automobile antifreeze solutions should not be used in HVAC systems because they contain silicates that may cause fouling. Silicates in automobile antifreeze are used to protect aluminum engine parts.

Note! Distilled or deionized water should be used for ethylene glycol solutions. City water may be treated with chlorine which is corrosive.

Systems for automatic makeup water should not be used since a leakage would contaminate the environment and dilute the antifreeze protection of the system.

Boiling Points Ethylene Glycol Solutions

For full table with Boiling Points - rotate the screen!

| Ethylene Glycol Solution (% by volume) | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Boiling Point | (oF) | 212 | 214 | 216 | 220 | 220 | 225 | 232 | 245 | 260 | 288 | 386 |

| (oC) | 100 | 101.1 | 102.2 | 104.4 | 104.4 | 107.2 | 111.1 | 118 | 127 | 142 | 197 | |

Increase in Flow required for a 50% Ethylene Glycol Solution

Increase in circulated flow for 50% ethylene glycol solutions compared with clean water are indicated in the table below

| Fluid Temperature | Flow Increase (%) | |

|---|---|---|

| (oF) | (oC) | |

| 40 | 4.4 | 22 |

| 100 | 37.8 | 16 |

| 140 | 60.0 | 15 |

| 180 | 82.2 | 14 |

| 220 | 104.4 | 14 |

Pressure Drop Correction and Combined Pressure Drop and Volume Flow Correction for 50% Ethylene Glycol Solution

Pressure drop correction and combined pressure drop and flow increase correction for 50% ethylene glycol solutions compared with clean water are indicated in the table below

| Fluid Temperature | Pressure Drop Correction with Flow Rates Equal (%) | Combined Pressure Drop and Flow Rate Correction (%) | |

|---|---|---|---|

| (oF) | (oC) | ||

| 40 | 4.4 | 45 | 114 |

| 100 | 37.8 | 10 | 49 |

| 140 | 60.0 | 0 | 32 |

| 180 | 82.2 | -6 | 23 |

| 220 | 104.4 | -10 | 18 |