Steam Pipes - Pressure Drop vs. Steam Flow

Steam pipes and pressure drop diagrams - imperial and metric units.

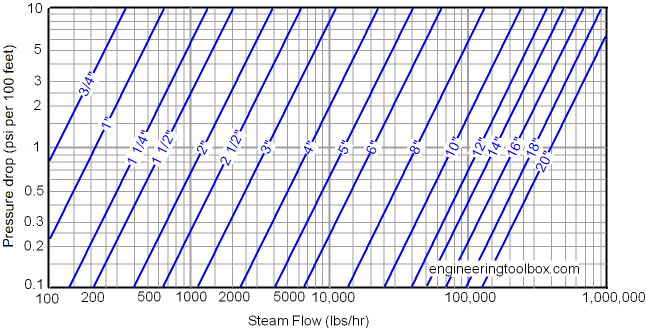

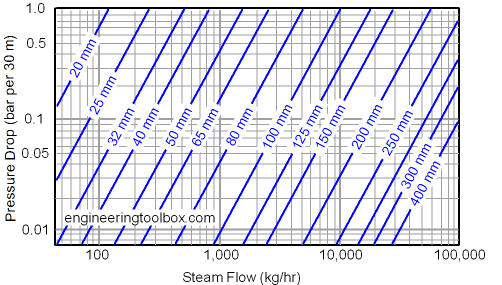

Pressure drop in steam pipes can be estimated with the diagrams below.

Imperial Units

The diagram is made for steam with pressure 100 psi schedule 40 steel pipe. For other pressures - use correction factors:

| Pressure (psi) | 0 | 5 | 10 | 30 | 60 | 90 | 100 | 110 | 150 | 200 | 250 | 300 |

| Factor | 6.9 | 5.2 | 4.3 | 2.4 | 1.5 | 1.1 | 1.0 | 0.92 | 0.70 | 0.55 | 0.45 | 0.38 |

- 1 lbs/hr = 1.26×10-4 kg/s

- 1 psi (lb/in2) = 6,894.8 Pa (N/m2) = 6.895×10-3 N/mm2 = 6.895×10-2 bar = 27.71 in H2O at 61 oF (16.7 oC) = 703.1 mm H2O at 61 oF (16.7 oC) = 2.0416 in mercury at 61 oF (16.7 oC) = 51.8 mm mercury at 61 oF (16.7 oC) = 703.6 kg/m2 = 0.06895 atm = 2.307 Ft. H2O

Metric Units

The diagram is made for steam with pressure 7 bar. For other pressures - multiply the pressure drop with correction factors:

| Pressure (bar) | 0 | 1 | 2 | 4 | 5 | 6 | 7 | 8.5 | 10 | 12 | 14 | 20 |

| Factor | 6.9 | 3.67 | 2.51 | 1.55 | 1.31 | 1.13 | 1.0 | 0.85 | 0.74 | 0.63 | 0.55 | 0.39 |

- 1 kg/h = 2.778×10-4 kg/s = 3.67×10-2 lb/min

- 1 bar = 105 Pa (N/m2) = 0.1 N/mm2 = 10,197 kp/m2 = 10.20 m H2O = 0.9869 atm = 14.50 psi (lbf/in2) = 106 dyn/cm2 = 750 mmHg