Pumps - Classifications

Centrifugal pumps vs. positive displacement pumps.

Pumps are in general classified as Centrifugal Pumps (or Roto-dynamic pumps) and Positive Displacement Pumps.

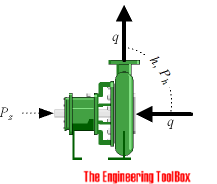

Centrifugal Pumps (Roto-dynamic pumps)

The centrifugal or roto-dynamic pump produce a head and a flow by increasing the velocity of the liquid through the machine with the help of the rotating vane impeller. Centrifugal pumps include radial, axial and mixed flow units.

Centrifugal pumps can be classified further as

- end suction pumps

- in-line pumps

- double suction pumps

- vertical multistage pumps

- horizontal multistage pumps

- submersible pumps

- self-priming pumps

- axial-flow pumps

- regenerative pumps

Positive Displacement Pumps

A positive displacement pump operates by alternating filling a cavity and then displacing a given volume of liquid. A positive displacement pump delivers a constant volume of liquid for each cycle independent of discharge pressure or head.

The positive displacement pump can be classified as:

- Reciprocating pumps - piston, plunger and diaphragm

- Power pumps

- Steam pumps

- Rotary pumps - gear, lobe, screw, vane, regenerative (peripheral) and progressive cavity

Selecting between Centrifugal or Positive Displacement Pumps

Selecting between a Centrifugal Pump or a Positive Displacement Pump is not always straight forward.

Flow Rate and Pressure Head

The two types of pumps behave very differently regarding pressure head and flow rate:

- The Centrifugal Pump has varying flow depending on the system pressure or head

- The Positive Displacement Pump has more or less a constant flow regardless of the system pressure or head. Positive Displacement pumps generally makes more pressure than Centrifugal Pump's.

Capacity and Viscosity

Another major difference between the pump types is the effect of viscosity on capacity:

- In a Centrifugal Pump the flow is reduced when the viscosity is increased

- In a Positive Displacement Pump the flow is increased when viscosity is increased

Liquids with high viscosity fills the clearances of Positive Displacement Pumps causing higher volumetric efficiencies and Positive Displacement Pumps are better suited for higher viscosity applications. A Centrifugal Pump becomes very inefficient at even modest viscosity.

Mechanical Efficiency

The pumps behaves different considering mechanical efficiency as well.

- Changing the system pressure or head has little or no effect on the flow rate in a Positive Displacement Pump

- Changing the system pressure or head may have a dramatic effect on the flow rate in a Centrifugal Pump

Net Positive Suction Head - NPSH

Another consideration is the Net Positive Suction Head - NPSH.

- In a Centrifugal Pump, NPSH varies as a function of flow determined by pressure

- In a Positive Displacement Pump, NPSH varies as a function of flow determined by speed. Reducing the speed of the Positive Displacement Pump pump, reduces the NPSH