Snow Melting Systems

Sizing snow melting systems - water and antifreeze.

A typical snow melting system should have a heating capacity of at least 100 Btu per hour per square feet (320 W/m2). This would melt up to 1.5 inch/hour (4 cm/h) snowfalls.

Solutions of 50% water and 50% antifreeze are common, but the solution used should always be adapted to local temperatures and system conditions. Note that metal pipes, like copper, will break if the solution inside the tubes freezes. Plastic pipes may in general freeze without breaking.

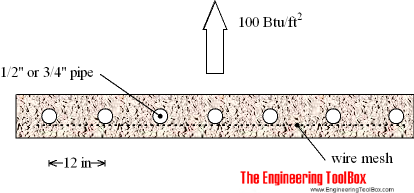

Coils in Concrete Layers

- entering temperature to the melting coils should be in range 120 - 130 oF (50 - 55 oF)

- distance between the coils should not exceed 12 inches (0.30 m)

- length of the coil should not exceed 140 feet (42 m) if 1/2" pipes are used. If 3/4" pipes are used the coil length can be extended to 280 feet (84 m)

- heating capacity is increased to 200 Btu per hour per square feet if the length with 1/2" tubes are reduced to 60 feet (150 feet with 3/4")

- concrete thickness above the tubes should be in range 1 1/4" to 1 1/2" (3 - 4 cm). The concrete layer must be reinforced with a wire mesh

Coils in Blacktop or Asphalt Layers

- entering temperature to the melting coils should be in range of 120 - 130 oF (50 - 55 oF)

- distance between the coils should not exceed 9 inches (0.23 m)

- length of the coil should not exceed 140 feet (42 m) if 1/2" pipes are used. If 3/4" pipes are used the coil length can be extended to 280 feet (84 m)

- heating capacity is increased to 200 Btu per hour per square feet if the length of 1/2" tubes are reduced to 60 feet. (150 feet with 3/4")

- blacktop or asphalt thickness above the tubes should be at least 1 1/2" (4 cm)