Conveyors - Capacities

Calculate conveyor capacities.

Conveyor capacity is determined by the belt speed, width and the angle of the belt - and can be expressed as

Q = ρ A v (1)

where

Q = conveyor capacity (kg/s, lb/s)

ρ = density of transported material (kg/m3, lb/ft3)

A = cross-sectional area of the bulk solid on the belt (m2, ft2)

v = conveyor belt velocity (m/s, ft/s)

The cross-sectional area of the bulk solid on the belt can be calculated as

A = U b2 (2)

where

U = non-dimensional cross-sectional area shape factor

b = contact perimeter between bulk material and belt (m, ft)

Non-dimensional cross-sectional area shape factors for various troughing belts are available from manufacturers' handbooks.

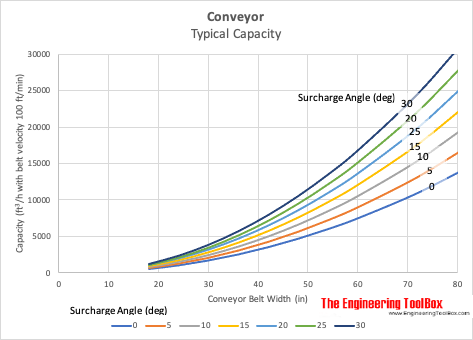

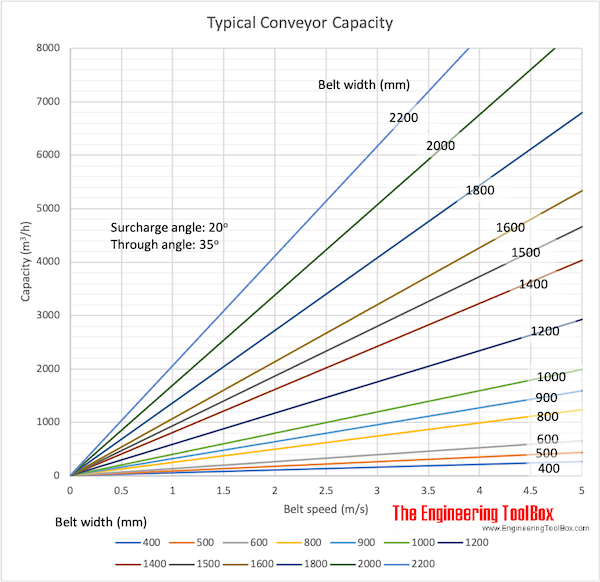

Typical Conveyor Capacity

- 1 in = 25.4 mm

- 1 ft3/h = 0.028 m3/h

- 1 ft/min = 5.08 x 10-3 m/s

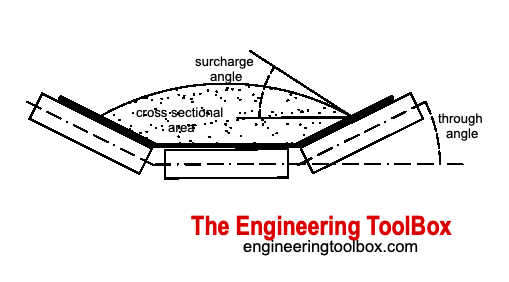

The product cross sectional area is defined by the idler trough shape and the product pile on top of the idler trough the trapezoid shape. This section on top of the trapezoid can be described with a circle and the angle this circle makes with the belt is the surcharge angle.

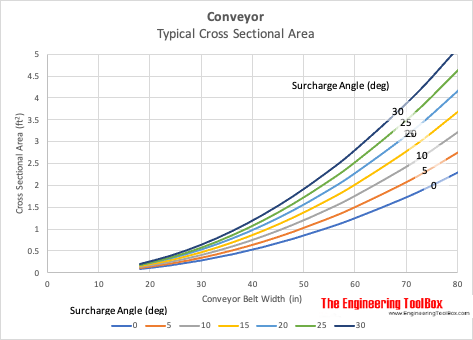

Typical Conveyor Cross Sectional Area

- 1 ft2 = 0.0929 m2

Typical Surcharge Angles

| Material | Surcharge Angle (degrees) |

|---|---|

| Alum | 25 |

| Alumina | 10 |

| Aluminium sulphate | 20 |

| Ammonium chloride | 10 |

| Ammonium nitrate | 25 |

| Asbestos shred | 30 |

| Ashes, coal, dry | 25 |

| Ashes, coal, wet | 25 |

| Ashes, fly | 30 |

| Ashes, gas producer, wet | 30 |

| Asphalt | 30 |

| Bagasse | 30 |

| Bark, wood | 30 |

| Barley | 10 |

| Bauxite, ground, dry | 20 |

| Bauxite, mine run | 20 |

| Beans | 5 |

| Beet, pulp, dry | 30 |

| Beets, whole | 20 |

| Borax | 20 |

| Brewers grain wet | 30 |

| Brick | 30 |

| Calcium carbide | 20 |

| Carbon black, pelletised | 5 |

| Cashew nuts | 30 |

| Cement, portland | 25 |

| Cement clinker | 25 |

| Chalk, lumpy | 10 |

| Chalk, 100 mesh and under | 25 |

| Charcoal | 25 |

| Chrome ore | 10 |

| Cinders, blast furnace | 10 |

| Cinder, coal | 20 |

| Clay, dry, fines | 20 |

| Clay, dry, lumpy | 20 |

| Coal, anthracite, 3mm and under | 20 |

| Coal, anthracite, sized | 10 |

| Coal, bituminous, mined 50 mesh and under | 30 |

| Coal, bituminous, mined and sized | 20 |

| Coal, lignite | 25 |

| Cocoa beans | 10 |

| Coke, breeze, 6mm and under | 20 |

| Concrete wet | 24 |

| Copper ore | 20 |

| Copper sulphate | 20 |

| Corn, ear | 25 |

| Cornmeal | 20 |

| Cottonseed cake | 20 |

| Dolomite | 18 |

| Earth, as dug, dry | 20 |

| Earth, wet, with clay | 30 |

| Feldspar | 25 |

| Flaxseed | 10 |

| Flour, wheat | 30 |

| Fluorspar | 30 |

| Foundry sand, old sand cores etc. | 25 |

| Fullers earth, dry | 10 |

| Glass batch | 10 |

| Granite, broken, 75mm lumps | 10 |

| Graphite, flake | 10 |

| Gravel, pebbles | 10 |

| Gypsum, dust, not-aerated | 20 |

| Gypsum, dust, aerated | 30 |

| Gypsum, 75mm lumps | 10 |

| Illmenite ore | 10 |

| Iron ore, coarse crushed | 20 |

| Iron ore, crushed fine | 20 |

| Lead ores | 10 |

| Lead oxide, light | 25 |

| Lignite, air dried | 10 |

| Lime, ground, 3mm and under | 30 |

| Lime, hydrated | 25 |

| Lime, pebble | 10 |

| Limestone, agricultural 3mm and under | 10 |

| Limestone, crushed | 25 |

| Linseed cake | 20 |

| Linseed meal | 20 |

| Magnesium chloride | 30 |

| Magnesium sulphate | 10 |

| Manganese ore | 25 |

| Manganese sulphate | 10 |

| Marble, crushed 12mm and under | 10 |

| Mica, ground | 20 |

| Mica, pulverized | 10 |

| Mica, flakes | 5 |

| Molybdenite, powdered | 20 |

| Mortar, wet | 24 |

| Nickel-cobalt | 10 |

| Oats | 10 |

| Peanuts in shells | 10 |

| Peas, dried | 5 |

| Phosphate, triple super ground fertilizer | 20 |

| Phosphate rock, pulverized | 25 |

| Potash ore | 10 |

| Pyrites, pellets | 10 |

| Quartz | 10 |

| Rice | 5 |

| Rock, crushed | 20 |

| Rubber, pelletised | 20 |

| Rubber, reclaim | 20 |

| Rye | 10 |

| Salt, common dry, coarse | 10 |

| Salt, common dry, fine | 10 |

| Sand, bank, damp | 30 |

| Sand, bank, dry | 20 |

| Sand, Silica, dry | 10 |

| Sandstone, broken | 20 |

| Sawdust | 25 |

| Shale, crushed | 25 |

| Sinter | 10 |

| Slag, blast furnace, crushed | 10 |

| Slate | 20 |

| Soap, beads or granules | 10 |

| Soap, chips | 10 |

| Soda ash, heavy | 20 |

| Soda ash, light | 25 |

| Sodium nitrate | 10 |

| Sodium phosphate | 10 |

| Soyabeans, whole | 10 |

| Starch | 10 |

| Steel trimmings | 20 |

| Sugar, granulated | 10 |

| Sugar, raw, cane | 20 |

| Sulphate powdered | 10 |

| Talc, powdered | 10 |

| Titanium ore | 10 |

| Titanium sponge | 30 |

| Vermiculite, expanded | 20 |

| Walnut shells, crushed | 20 |

| Wheat | 10 |

| Woodchips | 30 |

| Zinc ore, crushed | 25 |

| Zinc ore, roasted | 25 |

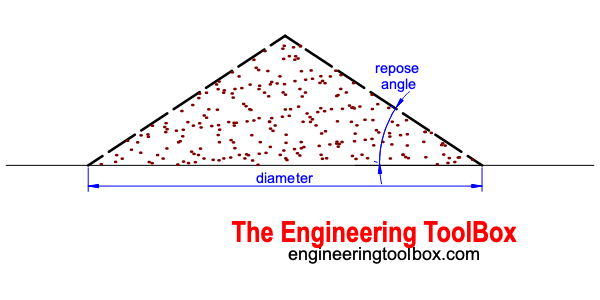

Surcharge Angle vs. Repose Angle

The angle of repose is considered the static rilling angle of a stockpile.

| Angle of Surcharge (degrees) | Angle of Repose (degrees) | Typical Products |

|---|---|---|

| 5 | 0 - 19 | Uniform sized |

| 10 | 20 - 29 | Rounded dry medium weight |

| 20 | 30 - 34 | Granular and lumpy (like coal or Clay) |

| 25 | 35 - 39 | Larger lumps (like coal, stone, ores) |

| 30 | 40 - 45 | Irregular (like wood chips) |

Typical Conveyor Capacity

The chart below indicates typical conveyor capacity vs. belt speed and belt width.

Multiply the volume capacity (m3/h) from the chart with the bulk density (kg/m3) of the product to estimate the weight capacity.

Related Topics

-

Miscellaneous

Engineering related topics like Beaufort Wind Scale, CE-marking, drawing standards and more.

Related Documents

-

Angles of Repose

Tipping or dumping angles for common materials like ashes, sand, earth, shingles and more. -

Belt Transmissions - Speed and Length of Belts

Calculate length and speed of belt and belt gearing. -

Belts - Power Transmission and Efficiency

Calculate belts power transmission and efficiency -

Conveyors - Belt Speed

Maximum conveyor belt speed. -

Conveyors - Load & Power Consumption

Conveyor required power consumption vs. load. -

Conveyors - Maximum Inclination vs. Product

Maximum conveyor inclination slopes for typical products. -

Pneumatic Powder and Solid Transport Systems

Pneumatic transport systems used to move powder and other solid products. -

Pneumatic Transport and Conveying - Carrying Velocities

Recommended air velocity for pneumatic transport of products like cement, coal, flour and more. -

Sieve Sizes vs. Mesh Designations

US commercial sieve sizes vs. mesh designations. -

Slurry Transports - Minimum Flow Velocities

Flow velocities in slurry transport systems to avoid settling of solids. -

Stockpile Volumes

Volume of natural stockpiles - cubic feet, yard, metre and decimetre.