Belt Transmissions - Speed and Length of Belts

Calculate length and speed of belt and belt gearing.

Belts (or chains) are used to transfer power (or convert torque) through rotational motion from one shaft to an other. Belt driven fans are common in heating, ventilation, air-conditioning and cooling (HVAC) systems. Chain are common in many transmission systems like bicycles and other.

- friction belts - transfer the power through friction between the pulley and the belt

- synchronous belts - transfer the power through a mechanical linkage between the teeth in the belt and the grooves in the pulley

Belt Length

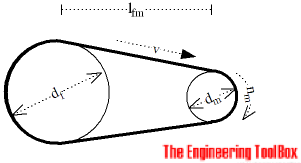

The length of the belt can be calculated as

lb = (dm π / 2) + (df π / 2) + (2 lfm) + ((df - dm)2/ (4 lfm)) (1)

where

lb = length of belt (mm, inches)

df = pulley (sheave) diameter fan (mm, inches)

dm = pulley (sheave) diameter motor (mm, inches)

π = 3.14..

lfm = center to center distance of fan and motor pulleys (mm, inches)

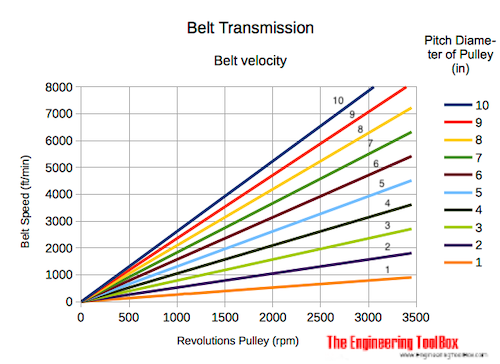

Belt Velocity

The velocity at which a belt travels may be expressed as

v = π dm nm / 12 (2)

where

v = velocity of belt (ft/min)

nm = revolutions motor (rpm)

- or alternatively in metric units:

vb = π dm nm / 60 (2b)

where

vb = velocity of belt (m/s)

dmb = diameter motor pulley (m)

| Pitch Diameter of Pulley (in) | Velocity (ft/min) | ||||||

|---|---|---|---|---|---|---|---|

| Revolutions Pulley - n -(rpm) | |||||||

| 850 | 1050 | 1075 | 1140 | 1550 | 1725 | 3450 | |

| 1 | 223 | 275 | 281 | 298 | 406 | 452 | 903 |

| 2 | 445 | 550 | 563 | 597 | 812 | 903 | 1806 |

| 3 | 668 | 825 | 844 | 895 | 1217 | 1355 | 2710 |

| 4 | 890 | 1100 | 1126 | 1194 | 1623 | 1806 | 3613 |

| 5 | 1113 | 1374 | 1407 | 1492 | 2029 | 2258 | 4516 |

| 6 | 1335 | 1649 | 1689 | 1791 | 2435 | 2710 | 5419 |

| 7 | 1558 | 1924 | 1970 | 2089 | 2841 | 3161 | 6322 |

| 8 | 1780 | 2199 | 2251 | 2388 | 3246 | 3613 | 7226 |

| 9 | 2003 | 2474 | 2533 | 2686 | 3652 | 4064 | 8129 |

| 10 | 2225 | 2749 | 2814 | 2985 | 4058 | 4516 | 9032 |

Belt Gearing

The relationship between the rotational speed of the motor and the fan and the disc diameter can be expressed as

df nf = dm nm (3)

or

nf = nm dm / df

Belt Gearing Calculator

Horsepower

If belt tension and belt velocity are known - horsepower transferred can be calculated as

Php = Fb vb / 33000 (4)

where

Php = power (hp)

Fb = belt tension (lbf)

vb = velocity of belt (ft/min)

If torque and revolution per minute are known - horsepower transferred can be calculated as

Php = T n / 5252 (4)

where

Php = power (hp)

T = torque (ft lbf)

n = revolutions per minute (rpm)

Speed Ratio

Speed ratio can be calculated as

SR = nf / ns (5)

where

SR = speed ratio

nf = revolutions per minute - fastest machine

ns = revolutions per minute - slowest machine

Related Topics

-

Mechanics

The relationships between forces, acceleration, displacement, vectors, motion, momentum, energy of objects and more. -

Ventilation Systems

Design of systems for ventilation and air handling - air change rates, ducts and pressure drops, charts and diagrams and more.

Related Documents

-

Belt driven Fans - Fan vs. Motor Speed

Fan vs. motor speed in belt driven fans. -

Belts - Power Transmission and Efficiency

Calculate belts power transmission and efficiency -

Belts - Pulley Diameters vs. Speed

The pulley laws - driver and driven - diameter and rpm -

Conn-Rod Mechanism

The connecting rod mechanism. -

Conveyors - Belt Speed

Maximum conveyor belt speed. -

Conveyors - Capacities

Calculate conveyor capacities. -

Conveyors - Load & Power Consumption

Conveyor required power consumption vs. load. -

Conveyors - Maximum Inclination vs. Product

Maximum conveyor inclination slopes for typical products. -

Efficiency of Small Machine Elements

Friction and efficiency in bearings and roller chains. -

Electrical Motors - Service Factors

Service factor - SF - is a measure of periodically overload capacity at which a motor can operate without beeing damaged. -

Fan Affinity Laws

The affinity laws can be used to calculate resulting volume capacity, head or power consumption when speed or wheel diameters are changed. -

Flywheels - Kinetic Energy

The kinetic energy stored in flywheels - the moment of inertia. -

Gear Reducing Formulas

Output torque, speed and horsepower with gears. -

Gear Trains - Bicycle Gearing Calculator

Gear train transmissions - bicycle gearing. -

Gears

Gears effort force vs. load force. -

Motors - Speed vs. Pulley Diameter

Pulley (Sheave) selection charts for motors ranging 850 - 3450 rpm. -

Pulleys

Pulleys, blocks and tackles. -

Torque - Work done and Power Transmitted

The work done and power transmitted by a constant torque.