Ultrasonic Doppler and Time of Flight Velocity and Volume Flow Meters

An basic introduction to the ultrasonic Doppler and Time of Flight Flow Meters.

Ultrasonic flow meters works in general after two different principles:

- The Doppler Effect Ultrasonic Flow meter

- The Time of Flight Ultrasonic Flow meter

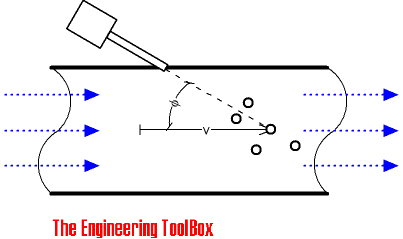

The Doppler Effect Ultrasonic Flow meter

The Doppler Effect Ultrasonic Flow meter use reflected ultrasonic sound to measure the fluid velocity. By measuring the frequency shift between the ultrasonic frequency source, the receiver, and the fluid carrier, the relative motion are measured.

The resulting frequency shift is named the Doppler Effect.

Fluid velocity can be calculated as

v = c (fr - ft) / (2 ft cos(Φ)) (1)

where

fr = received frequency

ft = transmission frequency

v = fluid flow velocity

Φ = relative angle between the transmitted ultrasonic beam and the fluid flow

c = velocity of sound in the fluid .. more about speed of sound

This method require there is some reflecting particles in the fluid. The method is not suitable for clear liquids.

Advantages with the Doppler Effect Ultrasonic Flow meter

Doppler meters may be used where other meters don't work. This might be liquid slurries, aerated liquids or liquids with some small or large amount on suspended solids. The advantages can be summarized to:

- Obstruct less flow

- Can be installed outside the pipes

- The pressure drop is equal to the equivalent length of a straight pipe1)

- Low flow cut off

- Corrosion resistant

- Relative low power consumption

1) Ultrasonic flow meters installed on the outside of the pipes will not have any influence on pressure loss in the pipe. Ultrasonic meters installed in the flow - like individual meters or similar - may influence on pressure loss like valves or similar.

Limitations with Doppler Effect Ultrasonic Flow meters

The Doppler flow meters performance are highly dependent on physical properties of the fluid, such as the sonic conductivity, particle density, and flow profile.

Non uniformity of particle distribution in the pipe cross section may result in a incorrectly computed mean velocity. The flowmeter accuracy is sensitive to velocity profile variations and to the distribution of acoustic reflectors in the measurement section.

Unlike other acoustic flow meters, Doppler meters are affected by changes in the liquid's sonic velocity. As a result, the meter is also sensitive to changes in density and temperature. These problems make Doppler flowmeters unsuitable for highly accurate measurement applications.

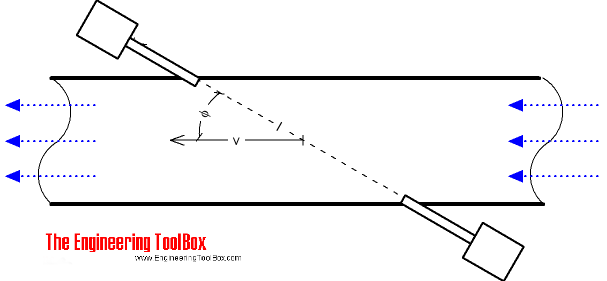

The Time of Flight Ultrasonic Flow meter

With the Time of Flight Ultrasonic Flow meter the time for the sound to travel between a transmitter and a receiver is measured. This method is not dependable on the particles in the fluid.

Two transmitters / receivers (transceivers) are located on each side of the pipe. The transmitters sends pulsating ultrasonic waves in a predefined frequency from one side to the other. The difference in frequency is proportional to the average fluid velocity.

The fluid velocity can be expressed as

v = ((t2 - t1) / (t2 t1)) (l / 2cos(Φ)) (2)

where

v = fluid flow velocity (m/s)

t1 = transmission time downstream (s)

t2 = transmission time upstream (s)

l = distance between sensors (m)

Φ = the relative angle between the transmitted ultrasonic beam and the fluid flow

Benefits with Ultrasonic Flow meters

- Obstruction less flow

- Pressure drop equal to an equivalent length of straight pipe

- Unaffected by changes in temperature, density or viscosity

- Bi-directional flow capability

- Low flow cutoff

- Corrosion-resistant

- Accuracy about 1% of flow rate

- Relative low power consumption

Limitations with Ultrasonic Flow meters

The operating principle for the ultrasonic flow meter requires reliability high frequency sound transmitted across the pipe. Liquid slurries with excess solids or with entrained gases may block the ultrasonic pulses.

Ultrasonic flow meters are not recommended for primary sludge, mixed liquor, aerobically digested sludge, dissolved air flotation thickened sludge and its liquid phase, septic sludge and activated carbon sludge.

Liquids with entrained gases cannot be measured reliably.