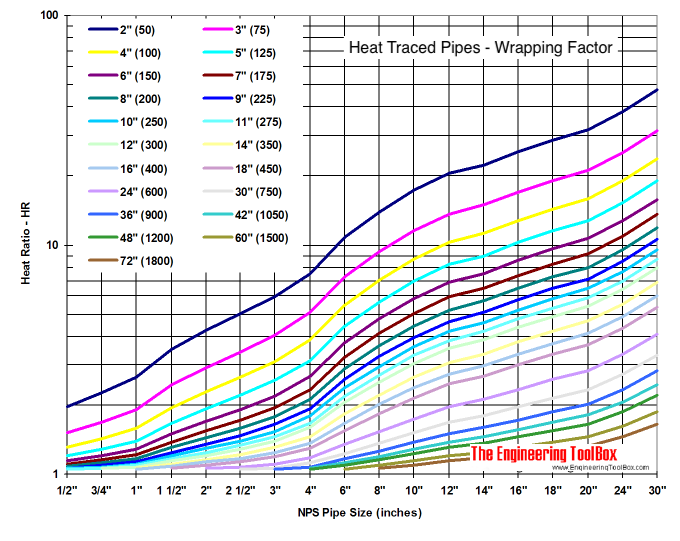

Heat Traced Pipes - Wrapping Factor

Wrapping factor when the heat loss from a pipe or tube is higher than the capacity of the heat trace cable.

When the heat loss from a pipe or tube is higher than the capacity of the heat trace cable - the cable must be spiral-wrapped around the pipe or tube.

The "heat loss - cable output" ratio can be calculated as

HR = Qhl / Qt (1)

HR = "heat loss - cable output" ratio

Qhl = heat loss from the insulated pipe or tube (W/m, Btu/h ft)

Qt = heat output from the heat trace (W/m, Btu/h ft)

If the "heat loss - cable output" ratio - HR - is larger than one, the cable must be wrapped. The pitch - the distance between the spirals - can be estimated from the diagram below.

Example - Heat Tracing

The heat loss from a 4" pipe is estimated to be three times (HR = 3) the heat output capacity of the tracing cable. The pitch - the distance between each spiral - can be estimated as indicated in the table below to 5 - 6 inches (125 - 150 mm).