Metals and Alloys - Young's Modulus of Elasticity

Elastic properties and Young's modulus for metals and alloys like cast iron, carbon steel and more.

It is convenient to express the elasticity of a material with the ratio stress to strain, a parameter also termed as the tensile elastic modulus or Young's modulus of the material - usually with the symbol - E.

- Young's modulus can be used to predict the elongation or compression of an object.

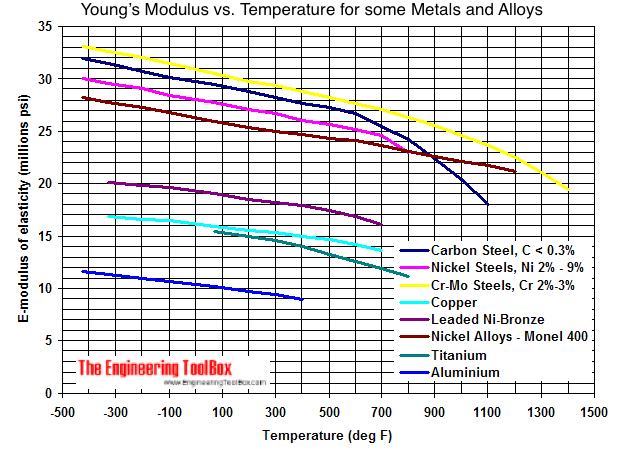

Modulus of Elasticity for some common metals at various temperatures according ASME B31.1-1995:

- 1 psi (lb/in2) = 1 psi (lb/in2) = 144 psf (lbf/ft2) = 6,894.8 Pa (N/m2) = 6.895x10-3 N/mm2

- T(oC) = 5/9[T(oF) - 32]

For full table with Higher Temperatures - rotate the screen!

| Metal | Young's Modulus of Elasticity - E - (106 psi) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (oC) | |||||||||||||||

| -200 | -129 | -73 | 21 | 93 | 149 | 204 | 260 | 316 | 371 | 427 | 482 | 538 | 593 | 649 | |

| Temperature (oF) | |||||||||||||||

| -325 | -200 | -100 | 70 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | |

| Cast iron | |||||||||||||||

| Gray cast iron | 13.4 | 13.2 | 12.9 | 12.6 | 12.2 | 11.7 | 11.0 | 10.2 | |||||||

| Steel | |||||||||||||||

| Carbon steel C <= 0.3% | 31.4 | 30.8 | 30.2 | 29.5 | 28.8 | 28.3 | 27.7 | 27.3 | 26.7 | 25.5 | 24.2 | 22.4 | 20.4 | 18.0 | |

| Carbon steel C => 0.3% | 31.2 | 30.6 | 30.0 | 29.3 | 28.6 | 28.1 | 27.5 | 27.1 | 26.5 | 25.3 | 24.0 | 22.2 | 20.2 | 17.9 | 15.4 |

| Carbon-molybdenum steels | 31.1 | 30.5 | 29.9 | 29.2 | 28.5 | 28.0 | 27.4 | 27.0 | 26.4 | 25.3 | 23.9 | 22.2 | 20.1 | 17.8 | 15.3 |

| Nickel steels Ni 2% - 9% | 29.6 | 29.1 | 28.5 | 27.8 | 27.1 | 26.7 | 26.1 | 25.7 | 25.2 | 24.6 | 23.0 | ||||

| Cr-Mo steels Cr 1/2% - 2% | 31.6 | 31.0 | 30.4 | 29.7 | 29.0 | 28.5 | 27.9 | 27.5 | 26.9 | 26.3 | 25.5 | 24.8 | 23.9 | 23.0 | 21.8 |

| Cr-Mo steels Cr 2 1/4% - 3% | 32.6 | 32.0 | 31.4 | 30.6 | 29.8 | 29.4 | 28.8 | 28.3 | 27.7 | 27.1 | 26.3 | 25.6 | 24.6 | 23.7 | 22.5 |

| Cr-Mo steels Cr 5% - 9% | 32.9 | 32.3 | 31.7 | 30.9 | 30.1 | 29.7 | 29.0 | 28.6 | 28.0 | 27.3 | 26.1 | 24.7 | 22.7 | 20.4 | 18.2 |

| Chromium steels Cr 12%, 17%, 27% | 31.2 | 30.7 | 30.1 | 29.2 | 28.5 | 27.9 | 27.3 | 26.7 | 26.1 | 25.6 | 24.7 | 23.2 | 21.5 | 19.1 | 16.6 |

| Austenitic steels (TP304, 310, 316, 321, 347) | 30.3 | 29.7 | 29.1 | 28.3 | 27.6 | 27.0 | 26.5 | 25.8 | 25.3 | 24.8 | 24.1 | 23.5 | 22.8 | 22.1 | 21.2 |

| Copper and copper alloys | |||||||||||||||

| Comp. and leaded-Sn bronze (C83600, C92200) | 14.8 | 14.6 | 14.4 | 14.0 | 13.7 | 13.4 | 13.2 | 12.9 | 12.5 | 12.0 | |||||

| Naval brass Si & Al bronze (C46400, C65500, C95200, C95400) | 15.9 | 15.6 | 15.4 | 15.0 | 14.6 | 14.4 | 14.1 | 13.8 | 13.4 | 12.8 | |||||

| Copper (C11000) | 16.9 | 16.6 | 16.5 | 16.0 | 15.6 | 15.4 | 15.0 | 14.7 | 14.2 | 13.7 | |||||

| Copper red brass Al-bronze (C10200, C12000, C12200, C12500, C14200, C23000, C61400) | 18.0 | 17.7 | 17.5 | 17.0 | 16.6 | 16.3 | 16.0 | 15.6 | 15.1 | 14.5 | |||||

| Nickel and Nickel Alloys | |||||||||||||||

| Monel 400 (N04400) | 27.8 | 27.3 | 26.8 | 26.0 | 25.4 | 25.0 | 24.7 | 24.3 | 24.1 | 23.7 | 23.1 | 22.6 | 22.1 | 21.7 | 21.2 |

| Titanium | |||||||||||||||

| Unalloyed titanium grades 1, 2, 3 and 7 | 15.5 | 15.0 | 14.6 | 14.0 | 13.3 | 12.6 | 11.9 | 11.2 | |||||||

| Aluminum and aluminum alloys | |||||||||||||||

| Grades 443, 1060, 1100, 3003, 3004, 6063 | 11.1 | 10.8 | 10.5 | 10.0 | 9.6 | 9.2 | 8.7 | ||||||||

- 1 psi (lb/in2) = 6,894.8 N/m2 (Pa)

- T(oC) = 5/9[T(oF) - 32]

Note! You can use the pressure unit converter to switch between units of Modulus of Elasticity.

Related Topics

-

Material Properties

Properties of gases, fluids and solids. Densities, specific heats, viscosities and more.

Related Documents

-

ASME/ANSI B36.10/19 - Carbon, Alloy and Stainless Steel Pipes - Dimensions

Pipe sizes, inside and outside diameters, wall thickness, schedules, moment of inertia, transverse area, weight of pipe filled with water - U.S. Customary Units. -

Bolt Stretching and Tensile Stress

Tensile stress and Hooke's Law. -

Copper, Zinc and Tin Alloys

Strength of Copper, Zinc and Tin alloys. -

Hooke's Law

Hooke's law - force, elongation and spring constant. -

Iron - Density, Specific Heats and Thermal Conductivities vs. Temperatures

Specific heat, density and thermal conductivity of iron related to temperature. -

Metal Alloys - Specific Heats

Specific heat of metal alloys like brass, bronze and more. -

Metals - Strength vs. Temperature

The influence of temperature on the strength of metals. -

Metals and Alloys - Bulk Modulus Elasticity

The Bulk Modulus - resistance to uniform compression - for some common metals and alloys. -

Modulus of Rigidity

Shear Modulus (Modulus of Rigidity) is the elasticity coefficient for shearing or torsion force. -

Poisson's Ratio

When a material is stretched in one direction it tends to get thinner in the other two directions. -

Restricted Thermal Expansion - Force and Stress

Stress and force when thermal expansion a pipe, beam or similar is restricted. -

Steels - Endurance Limits and Fatigue Stress

Endurance limits and fatigue stress for steels. -

Stiffness

Stiffness is resistance to deflection. -

Stress, Strain and Young's Modulus

Stress is force per unit area - strain is the deformation of a solid due to stress. -

Superheated Steam - Entropy

The entropy of steam superheated to temperatures above saturation points. -

Thermoplastics - Physical Properties

Physical properties of thermoplastics like ABS, PVC, CPVC, PE, PEX, PB and PVDF. -

Young's Modulus, Tensile Strength and Yield Strength Values for some Materials

Young's Modulus (or Tensile Modulus alt. Modulus of Elasticity) and Ultimate Tensile Strength and Yield Strength for materials like steel, glass, wood and many more.