System Curve and Pump Performance Curve

Utilize the system curve and the pump performance curve to select the proper pump for a particular application.

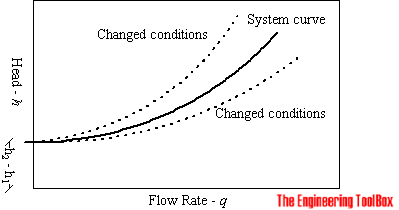

The System Curve

A fluid flow system is characterized with the System Curve - a graphical presentation of the Energy Equation.

The system head visualized in the System Curve above is a function of elevation - or the static head and the major and minor losses in the system and can be expressed as:

h = dh + hl (1)

where

h = system head (m)

dh = h2 - h1 = elevation (static) head difference between the inlet and outlet in the system (m)

hl = major and minor head loss in the system (m)

A generic expression of major and minor head loss is:

hl = k q2 (2)

where

q = flow rate

k = constant describing the total system characteristics - including all major and minor losses

Increasing the constant - k - by closing some valves, reducing the pipe size or similar - will increase the head loss and move the system curve upwards. The starting point for the curve - at no flow, will be the same.

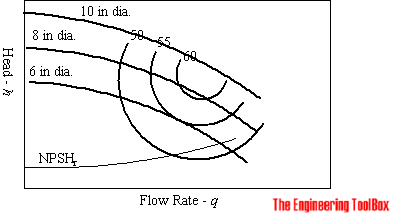

Pump Performance Curve

The pump characteristic is normally described graphically by the manufacturer as the pump performance curve. The pump performance curve describes the relation between the flowrate and the head for the actual pump. Other important information for a proper pump selection is also included - like efficiency curves, NPSHr curve, pump curves for several impeller diameters and different speeds, and power consumption.

Increasing the impeller diameter or speed increases the head and flow rate capacity - and the pump curve moves upwards.

The head capacity can be increased by connecting two or more pumps in series, or the flow rate capacity can be increased by connecting two or more pumps in parallel.

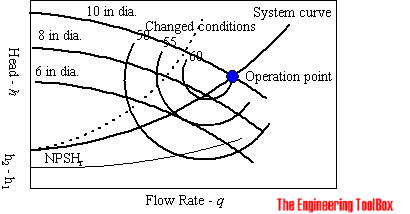

Selection of Pump

The proper pump can be selected by combining the System Curve and the Pump Curve:

The operating point is where the system curve and the actual pump curve intersects.

Best Efficiency Point - BEP

The best operating conditions will in general be close to the Best Efficiency Point - BEP.

Special considerations should be taken for applications where system conditions frequently changes during operation - like applications for heating and air conditioning systems or water supply systems with variable consumption and modulating valves.

Carry Out

When a pumps operates in the far right of its curve with poor efficiency - the pumps Carry Out.

Shutoff Head

The Shutoff Head is the head produced when the pump operates with fluid but with no flow rate.

Churn

A pump is in Churn when it operates at shutoff head or no flow.