Friction - Coefficients for Common Materials and Surfaces

Find friction coefficients for various material combinations, including static and kinetic friction values. Useful for engineering, physics, and mechanical design applications.

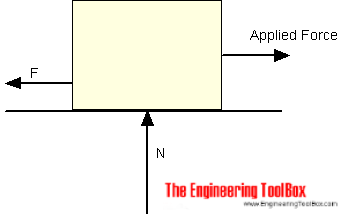

The friction force is the force exerted by a surface when an object moves across it - or makes an effort to move across it.

The frictional force can be expressed as

Ff = μ N (1)

where

Ff = frictional force (N, lb)

μ = static (μs) or kinetic (μk) frictional coefficient

N = normal force between the surfaces (N, lb)

There are at least two types of friction forces

- kinetic (sliding) friction force- when an object moves

- static friction force - when an object makes an effort to move

For an object pulled or pushed horizontally the normal force - N - is simply the gravity force - or weight:

N = Fg

= m ag (2)

where

Fg = gravity force - or weight (N, lb)

m = mass of object (kg, slugs)

ag = acceleration of gravity (9.81 m/s2, 32 ft/s2)

The friction force due to gravity (1) can with (2) be modified to

Ff = μ m ag (3)

Friction Force Calculator

Friction Coefficients for some Common Materials and Materials Combinations

| Materials and Material Combinations | Surface Conditions, Lubricant | Frictional Coefficient | ||

|---|---|---|---|---|

| Static - μstatic - | Kinetic (sliding) - μsliding - | |||

| Aluminum | Aluminum | Clean and Dry | 1.05 - 1.35 | 0.4 |

| Aluminum | Aluminum | Lubricated and Greasy | 0.3 | |

| Aluminum-bronze | Steel | Clean and Dry | 0.45 | |

| Aluminum | Mild Steel | Clean and Dry | 0.61 | 0.47 |

| Aluminum | Snow | Wet 0 oC | 0.4 | |

| Aluminum | Snow | Dry 0 oC | 0.35 | |

| Brake material2) | Cast iron | Clean and Dry | 0.4 | |

| Brake material2) | Cast iron (wet) | Clean and Dry | 0.2 | |

| Brass | Steel | Clean and Dry | 0.51 | 0.44 |

| Brass | Steel | Grease | 0.19 | |

| Brass | Steel | Castor oil | 0.11 | |

| Brass | Cast Iron | Clean and Dry | 0.3 | |

| Brass | Ice | Clean 0 oC | 0.02 | |

| Brass | Ice | Clean -80 oC | 0.15 | |

| Brick | Wood | Clean and Dry | 0.6 | |

| Bronze | Steel | Grease | 0.16 | |

| Bronze | Cast Iron | Clean and Dry | 0.22 | |

| Bronze - sintered | Steel | Grease | 0.13 | |

| Cadmium | Cadmium | Clean and Dry | 0.5 | |

| Cadmium | Cadmium | Grease | 0.05 | |

| Cadmium | Chromium | Clean and Dry | 0.41 | |

| Cadmium | Chromium | Grease | 0.34 | |

| Cadmium | Mild Steel | Clean and Dry | 0.46 | |

| Cast Iron | Cast Iron | Clean and Dry | 1.1 | 0.15 |

| Cast Iron | Cast Iron | Clean and Dry | 0.15 | |

| Cast Iron | Cast Iron | Grease | 0.07 | |

| Cast Iron | Oak | Clean and Dry | 0.49 | |

| Cast Iron | Oak | Grease | 0.075 | |

| Cast iron | Steel | Clean and Dry | 0.4 | |

| Cast iron | Steel | Clean and Dry | 0.23 | |

| Cast iron | Steel | Grease | 0.21 | 0.133 |

| Car tire | Asphalt | Clean and Dry | 0.72 | |

| Car tire | Grass | Clean and Dry | 0.35 | |

| Carbon (hard) | Carbon | Clean and Dry | 0.16 | |

| Carbon (hard) | Carbon | Grease | 0.12 - 0.14 | |

| Carbon | Steel | Clean and Dry | 0.14 | |

| Carbon | Steel | Grease | 0.11 - 0.14 | |

| Chromium | Chromium | Clean and Dry | 0.41 | |

| Chromium | Chromium | Grease | 0.34 | |

| Copper-Lead alloy | Steel | Clean and Dry | 0.22 | |

| Copper | Copper | Clean and Dry | 1.6 | |

| Copper | Copper | Grease | 0.08 | |

| Copper | Cast Iron | Clean and Dry | 1.05 | 0.29 |

| Copper | Steel | Clean and Dry | 0.53 | 0.36 |

| Copper | Steel | Grease | 0.18 | |

| Copper | Steel | Oleic acid | 0.18 | |

| Copper | Glass | Clean and Dry | 0.68 | 0.53 |

| Cotton | Cotton | Threads | 0.3 | |

| Diamond | Diamond | Clean and Dry | 0.1 | |

| Diamond | Diamond | Grease | 0.05 - 0.1 | |

| Diamond | Metals | Clean and Dry | 0.1 - 0.15 | |

| Diamond | Metal | Grease | 0.1 | |

| Garnet | Steel | Clean and Dry | 0.39 | |

| Glass | Glass | Clean and Dry | 0.9 - 1.0 | 0.4 |

| Glass | Glass | Grease | 0.1 - 0.6 | 0.09 - 0.12 |

| Glass | Metal | Clean and Dry | 0.5 - 0.7 | |

| Glass | Metal | Grease | 0.2 - 0.3 | |

| Glass | Nickel | Clean and Dry | 0.78 | |

| Glass | Nickel | Grease | 0.56 | |

| Graphite | Steel | Clean and Dry | 0.1 | |

| Graphite | Steel | Grease | 0.1 | |

| Graphite | Graphite (in vacuum) | Clean and Dry | 0.5 - 0.8 | |

| Graphite | Graphite | Clean and Dry | 0.1 | |

| Graphite | Graphite | Grease | 0.1 | |

| Hemp rope | Timber | Clean and Dry | 0.5 | |

| Horseshoe | Rubber | Clean and Dry | 0.68 | |

| Horseshoe | Concrete | Clean and Dry | 0.58 | |

| Ice | Ice | Clean 0 oC | 0.1 | 0.02 |

| Ice | Ice | Clean -12 oC | 0.3 | 0.035 |

| Ice | Ice | Clean -80 oC | 0.5 | 0.09 |

| Ice | Wood | Clean and Dry | 0.05 | |

| Ice | Steel | Clean and Dry | 0.03 | |

| Iron | Iron | Clean and Dry | 1.0 | |

| Iron | Iron | Grease | 0.15 - 0.20 | |

| Lead | Cast Iron | Clean and Dry | 0.43 | |

| Leather | Oak | Parallel to grain | 0.61 | 0.52 |

| Leather | Metal | Clean and Dry | 0.4 | |

| Leather | Metal | Grease | 0.2 | |

| Leather | Wood | Clean and Dry | 0.3 - 0.4 | |

| Leather | Clean Metal | Clean and Dry | 0.6 | |

| Leather | Cast Iron | Clean and Dry | 0.6 | 0.56 |

| Leather fiber | Cast iron | Clean and Dry | 0.31 | |

| Leather fiber | Aluminum | Clean and Dry | 0.30 | |

| Magnesium | Magnesium | Clean and Dry | 0.6 | |

| Magnesium | Magnesium | Grease | 0.08 | |

| Magnesium | Steel | Clean and Dry | 0.42 | |

| Magnesium | Cast Iron | Clean and Dry | 0.25 | |

| Masonry | Brick | Clean and Dry | 0.6 - 0.7 | |

| Mica | Mica | Freshly cleaved | 1.0 | |

| Nickel | Nickel | Clean and Dry | 0.7 - 1.1 | 0.53 |

| Nickel | Nickel | Grease | 0.28 | 0.12 |

| Nickel | Mild Steel | Clean and Dry | 0.64 | |

| Nickel | Mild Steel | Grease | 0.178 | |

| Nylon | Nylon | Clean and Dry | 0.15 - 0.25 | |

| Nylon | Steel | Clean and Dry | 0.4 | |

| Nylon | Snow | Wet 0 oC | 0.4 | |

| Nylon | Snow | Dry -10 oC | 0.3 | |

| Oak | Oak (parallel grain) | Clean and Dry | 0.62 | 0.48 |

| Oak | Oak (cross grain) | Clean and Dry | 0.54 | 0.32 |

| Oak | Oak (cross grain) | Grease | 0.072 | |

| Paper | Cast Iron | Clean and Dry | 0.20 | |

| Phosphor-bronze | Steel | Clean and Dry | 0.35 | |

| Platinum | Platinum | Clean and Dry | 1.2 | |

| Platinum | Platinum | Grease | 0.25 | |

| Plexiglas | Plexiglas | Clean and Dry | 0.8 | |

| Plexiglas | Plexiglas | Grease | 0.8 | |

| Plexiglas | Steel | Clean and Dry | 0.4 - 0.5 | |

| Plexiglas | Steel | Grease | 0.4 - 0.5 | |

| Polystyrene | Polystyrene | Clean and Dry | 0.5 | |

| Polystyrene | Polystyrene | Grease | 0.5 | |

| Polystyrene | Steel | Clean and Dry | 0.3 - 0.35 | |

| Polystyrene | Steel | Grease | 0.3 - 0.35 | |

| Polyethylene | Polytehylene | Clean and Dry | 0.2 | |

| Polyethylene | Steel | Clean and Dry | 0.2 | |

| Polyethylene | Steel | Grease | 0.2 | |

| Rubber | Rubber | Clean and Dry | 1.16 | |

| Rubber | Cardboard | Clean and Dry | 0.5 - 0.8 | |

| Rubber | Dry Asphalt | Clean and Dry | 0.9 | 0.5 - 0.8 |

| Rubber | Wet Asphalt | Clean and Dry | 0.25 - 0.75 | |

| Rubber | Dry Concrete | Clean and Dry | 0.6 - 0.85 | |

| Rubber | Wet Concrete | Clean and Dry | 0.45 - 0.75 | |

| Silk | Silk | Clean | 0.25 | |

| Silver | Silver | Clean and Dry | 1.4 | |

| Silver | Silver | Grease | 0.55 | |

| Sapphire | Sapphire | Clean and Dry | 0.2 | |

| Sapphire | Sapphire | Grease | 0.2 | |

| Silver | Silver | Clean and Dry | 1.4 | |

| Silver | Silver | Grease | 0.55 | |

| Skin | Metals | Clean and Dry | 0.8 - 1.0 | |

| Steel | Steel | Clean and Dry | 0.5 - 0.8 | 0.42 |

| Steel | Steel | Grease | 0.16 | |

| Steel | Steel | Castor oil | 0.15 | 0.081 |

| Steel | Steel | Stearic Acid | 0.15 | |

| Steel | Steel | Light mineral oil | 0.23 | |

| Steel | Steel | Lard | 0.11 | 0.084 |

| Steel | Steel | Graphite | 0.058 | |

| Steel | Graphite | Clean and Dry | 0.21 | |

| Straw Fiber | Cast Iron | Clean and Dry | 0.26 | |

| Straw Fiber | Aluminum | Clean and Dry | 0.27 | |

| Tarred fiber | Cast Iron | Clean and Dry | 0.15 | |

| Tarred fiber | Aluminum | Clean and Dry | 0.18 | |

| Polytetrafluoroethylene (PTFE) (Teflon) | Polytetrafluoroethylene (PTFE) | Clean and Dry | 0.04 | 0.04 |

| Polytetrafluoroethylene (PTFE) | Polytetrafluoroethylene (PTFE) | Grease | 0.04 | |

| Polytetrafluoroethylene (PTFE) | Steel | Clean and Dry | 0.05 - 0.2 | |

| Polytetrafluoroethylene (PTFE) | Snow | Wet 0 oC | 0.05 | |

| Polytetrafluoroethylene (PTFE) | Snow | Dry 0 oC | 0.02 | |

| Tungsten Carbide | Steel | Clean and Dry | 0.4 - 0.6 | |

| Tungsten Carbide | Steel | Grease | 0.1 - 0.2 | |

| Tungsten Carbide | Tungsten Carbide | Clean and Dry | 0.2 - 0.25 | |

| Tungsten Carbide | Tungsten Carbide | Grease | 0.12 | |

| Tungsten Carbide | Copper | Clean and Dry | 0.35 | |

| Tungsten Carbide | Iron | Clean and Dry | 0.8 | |

| Tin | Cast Iron | Clean and Dry | 0.32 | |

| Tire, dry | Road, dry | Clean and Dry | 1 | |

| Tire, wet | Road, wet | Clean and Dry | 0.2 | |

| Wax, ski | Snow | Wet 0 oC | 0.1 | |

| Wax, ski | Snow | Dry 0 oC | 0.04 | |

| Wax, ski | Snow | Dry -10 oC | 0.2 | |

| Wood | Clean Wood | Clean and Dry | 0.25 - 0.5 | |

| Wood | Wet Wood | Clean and Dry | 0.2 | |

| Wood | Clean Metal | Clean and Dry | 0.2 - 0.6 | |

| Wood | Wet Metals | Clean and Dry | 0.2 | |

| Wood | Stone | Clean and Dry | 0.2 - 0.4 | |

| Wood | Concrete | Clean and Dry | 0.62 | |

| Wood | Brick | Clean and Dry | 0.6 | |

| Wood - waxed | Wet snow | Clean and Dry | 0.14 | 0.1 |

| Wood - waxed | Dry snow | Clean and Dry | 0.04 | |

| Zinc | Cast Iron | Clean and Dry | 0.85 | 0.21 |

| Zinc | Zinc | Clean and Dry | 0.6 | |

| Zinc | Zinc | Grease | 0.04 | |

Kinetic or sliding frictional coefficient only when there is a relative motion between the surfaces.

Note! It is commonly thought that the static coefficients of friction are higher than the dynamic or kinetic values. This is a very simplistic statement and quite misleading for brake materials. With many brake materials the dynamic coefficient of friction quoted is an "average" value when the material is subject to a range of sliding speeds, surface pressures and most importantly operating temperatures. If the static situation is considered at the same pressure, but at ambient temperature, then the static coefficient of friction is often significantly LOWER than the average quoted dynamic value. It can be as low as 40 - 50% of the quoted dynamic value.

Kinetic (Sliding) versus Static Frictional Coefficients

Kinetic or sliding frictional coefficients are used with relative motion between objects. Static frictional coefficients are used for objects without relative motion. Note that static coefficients are somewhat higher than the kinetic or sliding coefficients. More force are required to start a motion

Example - Friction Force

A 100 lb wooden crate is pushed across a concrete floor. The friction coefficient between the object and the surface is 0.62. The friction force can be calculated as

Ff = 0.62 (100 lb)

= 62 (lb)

- 1 lb = 0.4536 kg

Example - Car, Braking, Friction Force and Required Distance to Stop

A car with mass 2000 kg drives with speed 100 km/h on a wet road with friction coefficient 0.2.

Note! - The friction work required to stop the car is equal to the kinetic energy of the car.

The kinetic energy of the car is

Ekinetic = 1/2 m v2 (4)

where

Ekinetic = kinetic energy of the moving car (J)

m = mass (kg)

v = velocity (m/s)

Ekinetic = 1/2 (2000 kg) ((100 km/h) (1000 m/km) / (3600 s/h))2

= 771605 J

The friction work (energy) to stop the car can be expressed as

Wfriction = Ff d (5)

where

Wfriction = friction work to stop the car (J)

Ff = friction force (N)

d = braking (stopping) distance (m)

Since the kinetic energy of the car is converted to friction energy (work) - we have the expression

Ekinetic = Wfriction (6)

The friction force Ff can be calculated from (3)

Ff = μ m g

= 0.2 (2000 kg) (9.81 m/s2)

= 3924 N

The stop distance for the car can be calculated by modifying (5) to

d = Wfriction/ Ff

= (771605 J) / (3924 N)

= 197 m

Note! - since the mass of the car is present on both sides of eq. 6 it cancels out. The stop distance is not dependent on the mass of the car.

"Laws of Friction"

Unlubricated Dry Surfaces

- for low pressure the friction is proportional to the normal force between the surfaces. With rising pressure the friction will not rise proportionally. With extreme pressure friction will rise and surfaces seize.

- at moderate pressure the friction force - and coefficient - is not dependent of the surface areas in contact as long as the normal force is the same. With extreme pressure friction will rice and surfaces seize.

- at very low velocity between the surfaces the friction is independent of the velocity of rubbing. With increased velocity the the friction decrease.

Lubricated Surfaces

- friction force is almost independent of pressure - normal force - if the surfaces are flooded with lubricant

- friction varies with speed at low pressure. At higher pressure the minimum friction is at velocity 2 ft/s (0.7 m/s) and friction increases with approximately square root of velocity afterwards.

- friction varies with temperature

- for well lubricated surfaces the friction is almost independent of surface material

Typically steel on steel dry static friction coefficient 0.8 drops to 0.4 when sliding is initiated - and steel on steel lubricated static friction coefficient 0.16 drops to 0.04 when sliding is initiated.

Related Searches

friction coefficient • static friction • kinetic friction • material friction • engineering friction data • surface friction • mechanical design • tribology • material properties • friction tables •