AWG - Wire Gauge Sizes: Current Ratings, Charts, Measurements, and Conversion Guide

Amp ratings vs. US AWG wire gauge.

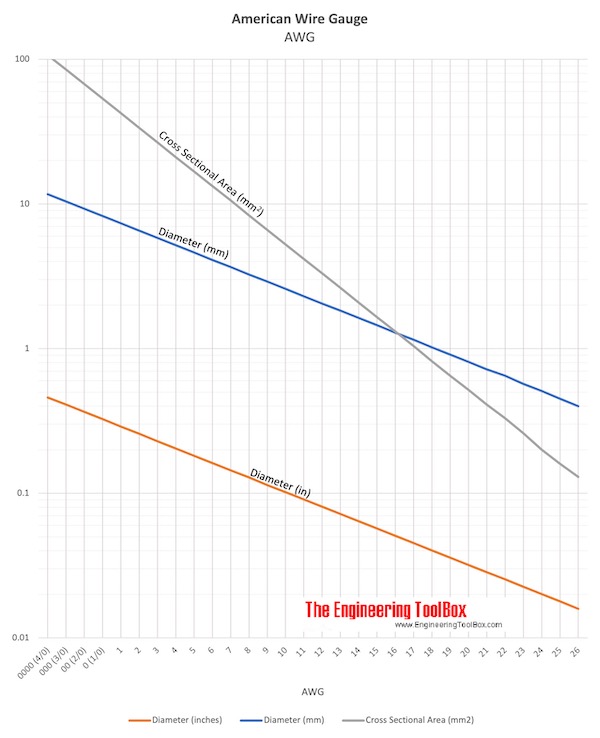

The AWG - American Wire Gauge - is used as a standard method denoting wire diameter, measuring the diameter of the conductor (the bare wire) with the insulation removed. AWG is sometimes also known as Brown and Sharpe (B&S) Wire Gauge.

The AWG table below is for a single, solid, round conductor. Because of the small gaps between the strands in a stranded wire, a stranded wire with the same current-carrying capacity and electrical resistance as a solid wire, always have a slightly larger overall diameter.

The higher the number - the thinner the wire. Typical household wiring is AWG number 12 or 14. Telephone wire is typical AWG 22, 24, or 26.

The table below indicates the current ratings of PVC-insulated single and multicore wiring cables. Be aware that the current load depends on installation method - the enclosure - and how well the resistance heat is removed from the cable. Operating temperature of the conductor, ambient temperature and type of conductor insulation is important. Always check the manufactures data before detailed engineering.

For full table with Single Core and Multi Core Current Ratings - rotate the screen!

| AWG | Diameter (mm) | Diameter (in) | Square (mm2) | Resistance Copper (ohm/1000m) | Resistance Aluminum (ohm/1000m) | Typical Max. Current Load Ratings - Copper (amps) 1) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Single Core | Multicore | ||||||||||

| up to 3 cores | 4 - 6 cores | 7 - 24 cores | 25 - 42 cores | 43 and above | |||||||

| 40 | 0.08 | . | 0.0050 | 3448 | 5300 | ||||||

| 39 | 0.09 | . | 0.0064 | 2693 | 4141 | ||||||

| 38 | 0.10 | 0.0040 | 0.0078 | 2210 | 3397 | ||||||

| 37 | 0.11 | 0.0045 | 0.0095 | 1810 | 2789 | ||||||

| 36 | 0.13 | 0.0050 | 0.013 | 1326 | 2038 | ||||||

| 35 | 0.14 | 0.0056 | 0.015 | 1120 | 1767 | ||||||

| 34 | 0.16 | 0.0063 | 0.020 | 862 | 1325 | ||||||

| 33 | 0.18 | 0.0071 | 0.026 | 663 | 1019 | ||||||

| 32 | 0.20 | 0.0080 | 0.031 | 556 | 855 | ||||||

| 30 | 0.25 | 0.010 | 0.049 | 352 | 541 | ||||||

| 28 | 0.33 | 0.013 | 0.080 | 216 | 331 | ||||||

| 27 | 0.36 | 0.014 | 0.096 | 180 | 276 | ||||||

| 26 | 0.41 | 0.016 | 0.13 | 133 | 204 | ||||||

| 25 | 0.45 | 0.018 | 0.16 | 108 | 166 | ||||||

| 24 | 0.51 | 0.020 | 0.20 | 88 | 133 | 3.5 | 2 | 1.6 | 1.4 | 1.2 | 1.0 |

| 22 | 0.64 | 0.025 | 0.33 | 52 | 80 | 5.0 | 3 | 2.4 | 2.1 | 1.8 | 1.5 |

| 20 | 0.81 | 0.032 | 0.50 | 34 | 53 | 6.0 | 5 | 4.0 | 3.5 | 3.0 | 2.5 |

| 18 | 1.0 | 0.040 | 0.82 | 21 | 32 | 9.5 | 7 | 5.6 | 4.9 | 4.2 | 3.5 |

| 16 | 1.3 | 0.051 | 1.3 | 13 | 20 | 15 | 10 | 8.0 | 7.0 | 6.0 | 5.0 |

| 14 | 1.6 | 0.064 | 2.1 | 8.2 | 13 | 24 | 15 | 12 | 10 | 9.0 | 7.5 |

| 13 | 1.8 | 0.072 | 2.6 | 6.6 | 10 | ||||||

| 12 | 2.1 | 0.081 | 3.3 | 5.2 | 8.0 | 34 | 20 | 16 | 14 | 12 | 10 |

| 10 | 2.6 | 0.10 | 5.3 | 3.3 | 5.0 | 52 | 30 | 24 | 21 | 18 | 15 |

| 8 | 3.3 | 0.13 | 8.3 | 2.1 | 3.2 | 75 | 40 | 32 | 28 | 24 | 20 |

| 6 | 4.1 | 0.17 | 13.3 | 1.3 | 2.0 | 95 | 55 | 44 | 38 | 33 | 27 |

| 4 | 5.2 | 0.20 | 21.2 | 0.81 | 1.3 | 120 | 70 | 56 | 49 | 42 | 35 |

| 3 | 26.7 | 0.65 | 0.99 | 154 | 80 | 64 | 56 | 48 | 40 | ||

| 2 | 6.5 | 0.26 | 33.6 | 0.51 | 0.79 | 170 | 95 | 76 | 66 | 57 | 57 |

| 1 | 7.4 | 0.29 | 42.4 | 0.41 | 0.63 | 180 | 110 | 88 | 77 | 66 | 55 |

| 0 (1/0) | 8.3 | 0.33 | 53.5 | 0.32 | 0.50 | 200 | |||||

| 00 (2/0) | 9.3 | 0.37 | 67.4 | 0.26 | 0.39 | 225 | |||||

| 000 (3/0) | 10.4 | 0.41 | 85.0 | 0.20 | 0.32 | 275 | |||||

| 0000 (4/0) | 11.7 | 0.46 | 107 | 0.16 | 0.25 | 325 | |||||

| 250 | 127 | 345 | |||||||||

| 300 | 152 | 390 | |||||||||

| 400 | 178 | 415 | |||||||||

1) Current ratings for up to 1000 V , PVC-insulated single and multicore wiring cables, ambient temperature up to 30 oC

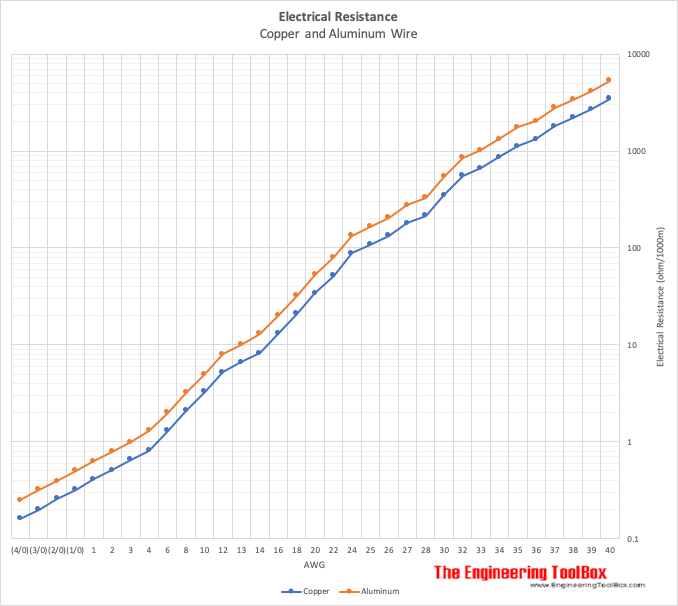

Values for resistance are based on electrical resistivity for copper 1.724×10-8 Ω m (0.0174 μΩ m) and electrical resistivity for aluminum 2.65×10-8 Ω m (0.0265 μΩ m).

The higher the gauge number, the smaller the diameter, and the thinner the wire.

Because of less electrical resistance a thicker wire carries more current with less voltage drop than a thinner wire. For longer distances it may be necessary to increase wire diameter - reducing the gauge - to limit voltage drop.

Correction-factors at ambient temperature above 30 oC

- ambient temperature 31 - 40 oC : correction factor = 0.82

- ambient temperature 4 1 - 45 oC : correction factor = 0.71

- ambient temperature 45 - 50 oC : correction factor = 0.58