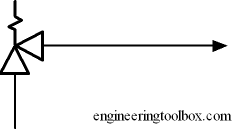

Spring Operated Safety Valves in Liquid Systems

Calculate spring operated relief valves in liquid systems.

The minimum discharge area of a spring operated relief safety valve in a liquid system can be calculated as

A = q SG1/2 / (28.14 Kbp Kvisc dp1/2) (1)

where

A = discharge area (Square Inches)

q = relieving capacity (Gallons per Minute)

SG =Specific Gravity of the fluid

Kbp = capacity correction for back pressure - 1.0 for atmospheric pressure systems

Kvisc = correction factor due to velocity - 1.0 for most water systems

dp = differential pressure - set pressure (psig) + over pressure (psig) - back pressure (psig)