Duct Sizing - the Equal Friction Method

The equal friction method for sizing air ducts is easy and straightforward to use.

The equal friction method for sizing air ducts is often preferred because it is quite easy to use. The method can be summarized to

- Compute the necessary air volume flow (m3/s, cfm) in every room and branch of the system

- Use 1) to compute the total air volume (m3/s, cfm) in the main system

- Determine the maximum acceptable airflow velocity in the main duct

- Determine the major pressure drop in the main duct

- Use the major pressure drop for the main duct as a constant to determine the duct sizes throughout the distribution system

- Determine the total resistance in the duct system by multiplying the static resistance with the equivalent length of the longest run

- Compute balancing dampers

1. Compute the air volume in every room and branch

Use the actual heat, cooling or air quality requirements for the rooms and calculate required air volume flow - q.

2. Compute the total volume flow in the system

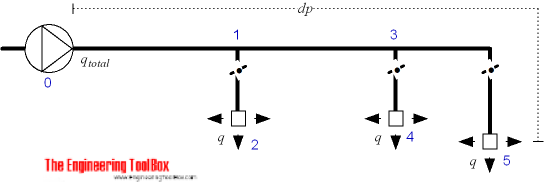

Make a simplified diagram of the system like the one above.

Use 1) to summarize and accumulate total air volume flow - qtotal - in the system.

Note! Be aware that maximum load conditions almost never occurs in all rooms at the same time. Avoid over-sizing the main system by multiplying the accumulated volume with a factor less than one (this is probably the hard part - and for larger systems sophisticated computer-assisted indoor climate calculations are often required).

3. Determine maximum acceptable airflow velocities in the main ducts

Determine maximum velocity in the main ducts on basis of application environment. To avoid unacceptable noise levels - keep maximum velocities within limits

- comfort systems - air velocity 4 to 7 m/s (13 to 23 ft/s)

- industrial systems - air velocity 8 to 12 m/s (26 to 40 ft/s)

- high speed systems - air velocity 10 to 18 m/s (33 to 60 ft/s)

Use maximum velocity limit when selecting size of main ducts.

4. Determine the static pressure drop in main duct

Use a pressure drop table or similar to determine static pressure drop in main duct.

5. Determine the duct sizes throughout the system

Use the static pressure drop from 4) as a constant to determine the ducts sizes throughout the system. Use the air volumes calculated in 1) for the calculation. Select the duct sizes with the pressure drop for the actual ducts as close to the main duct pressure drop as possible.

6. Determine the total resistance in the system

Use the static pressure from 4) to calculate the pressure drop through the longest part of the duct system. Add minor loss by using equivalent lengths or minor loss coefficients as used in the example spreadsheet below.

7. Calculate balancing dampers

Use the total resistance in 6) and the volume flow throughout the system to calculate dampers and their theoretical pressure loss.

Note about the Equal Friction Method

The equal friction method is straightforward and easy to use and gives an automatic reduction of air flow velocities through the system. The reduced velocities are in general within the noise limits of the application environment.

Typical values used for friction loss are 0.1 in H2O/100 ft (0.85 Pa/m) for supply ducts and 0.08 in H2O/100 ft (0.65 Pa/m) for return ducts.

The method can increase the numbers of reductions compared to other methods and often a poorer pressure balance in the system require more adjusting dampers. This may increase the system cost compared to other methods.

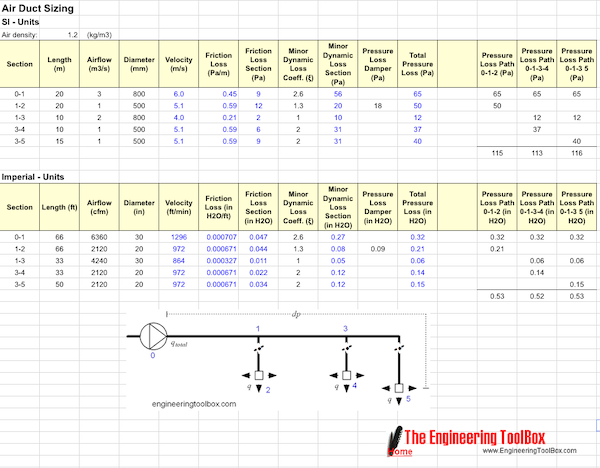

Example Template - The Equal Friction Method

The equal friction method can be done manual or more or less semi automatic with the spreadsheet template below.

This template is based on the figure above. Customize sections, airflows, duct sizes and minor dynamic loss coefficients - add pressure loss paths and evaluate and reconfigure the system to fit your criteria. Summarize pressure loss for each path and add damper pressure losses manually to balance the system.

The Google Docs spreadsheet template can be opened and copied here! The spreadsheet can also be downloaded as an excel file. Use the Google Docs "File" menu on the top of the template.

Related Topics

-

Ventilation Systems

Design of systems for ventilation and air handling - air change rates, ducts and pressure drops, charts and diagrams and more.

Related Documents

-

Air Duct Components - Minor Dynamic Loss Coefficients

Minor loss (pressure or head loss) coefficients for air duct components. -

Air Duct Velocities

Typical air duct velocities in applications like ventilation systems or compressed air systems. -

Air Ducts - Friction Loss Diagram

A major friction loss diagram for air ducts - Imperial units ranging 10 - 100 000 cfm. -

Air Ducts - Friction Loss Diagram

A major friction loss diagram for air ducts - SI units. -

Air Ducts - Major Friction Head Loss, Online Calculator

Head loss or major loss in air ducts - equations and online calculator for rectangular and circular ducts - Imperial and SI units. -

Circular Ducts - Dimensions

Standard size of circular ventilation air ducts. -

Design of Ventilation Systems

Design procedure for ventilation systems - air flow rates, heat and cooling loads, air shifts according occupants, air supply principles. -

Duct Systems - Pressure Classifications

Duct systems are commonly divided into three pressure classifications. -

Duct Velocity

Calculate velocities in circular and rectangular ducts - imperial and SI-units - online calculator. -

Ducts Sizing - the Velocity Reduction Method

The velocity reduction method can be used when sizing air ducts. -

Equivalent Diameter - Rectangular vs. Circular HVAC Ducts

Rectangular equivalent diameter for air flows between 100 - 50000 cfm. -

Equivalent Length Method - Minor Pressure Loss in Piping Systems

Calculate minor pressure loss in piping systems with the Equivalent Pipe Length Method. -

HVAC Dampers - Pressure Loss

Pressure head loss in HVAC dampers. -

PVC Pipes - Equivalent Length and Pressure Loss in Fittings

Minor loss in PVC and CPVC fittings expressed as equivalent length of straight pipe. -

Rectangular Ducts - Dimensions

Commonly used metric dimensions for rectangular air ducts in ventilation systems. -

Sizing Circular Ducts

A rough guide to maximum air volume capacity of circular ducts in comfort, industrial and high speed ventilation systems.