Centrifugal Pumps - Capacity Modulation

Modulating pumps to adapt capacities to variable process demands.

It is often necessary to adapt pump capacities to temporary or permanent changes in the process demand.

The capacity of a centrifugal pump can be regulated either at

- constant speed, or

- varying speed

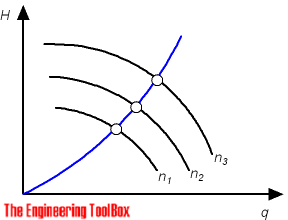

Capacity Regulating by Varying Speed

Speed modulation is energy efficient since the energy to the pump is reduced with by decreasing the impeller speed.

The speed of the pump can be varied with

- hydraulic/hydrostatic drives - hydraulic coupling between input and output shaft - speed ratio 5 to 1 is controlled by adjusting the volume of oil in the coupling

- mechanical drives - belt and sheave drive

- eddy current drive/clutch - magnetic coupling transfer load torque between input and output shaft

- variable speed drives - inverters - AC drives - adjustable frequency drives - operates by varying the frequency and voltage to the electric motor

The change in power consumption, head and volume rate can be estimated with the help of the affinity laws.

Modulating Capacity at Constant Speed

Capacity can be regulated at constant speed by

- throttling

- bypassing flow

- changing impeller diameter

- modifying the impeller

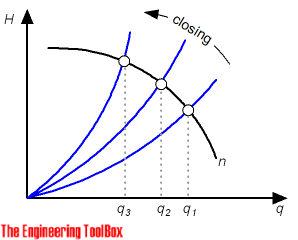

Throttling

Throttling can be carried out by opening and closing a discharge valve.

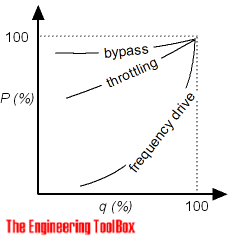

Throttling is energy inefficient since the energy to the pump is not reduced. Energy is wasted by increasing the dynamic loss.

Bypassing Flow

The discharge capacity can be regulated by leading a part of the discharge flow back to the suction side of the pump. Bypassing the flow is energy inefficient since the energy to the pump is not reduced.

Changing the Impeller Diameter

Reducing the impellers diameter is a permanent change and the method can be used where the change in process demand is not temporary. The method may be energy efficient if the motor is changed and the energy consumption reduced.

The change in power consumption, head and volume rate can be estimated with the help of the affinity laws.

Modifying the Impeller

The flow rate and the head can be modulated by changing the pitch of the blades. Complicated and seldom used.

Pump Regulation and Power Consumption

Comparing power consumption:

Related Topics

-

Pumps

Design of pumping systems and pipelines. With centrifugal pumps, displacement pumps, cavitation, fluid viscosity, head and pressure, power consumption and more. -

Water Systems

Design of hot and cold water service and utility systems with properties, capacities, sizing of pipe lines and more.

Related Documents

-

BEP - the Best Efficiency Point of a Pump

BEP is where the pump is most efficient. -

Centrifugal Pumps

An introduction to Centrifugal Pumps. -

Pump - Temperature Rise vs. Volume Flow

Calculate temperature rise vs. volume flow in pumps. -

Pumps - Affinity Laws

Turbo machines affinity laws can be used to calculate volume capacity, head or power consumption in centrifugal pumps when changing speed or wheel diameters. -

Pumps - Head vs. Pressure

Converting head (ft or m) to pressure (psi or bar, kg/cm2) and vice versa. -

Pumps - Specific Speed

Characterizing of impeller types in pumps in a unique and coherent manner.