Hydraulic Pump Volume Capacity

Calculate hydraulic pump volume capacity.

Hydraulic pump capacity can be estimated in Imperial units as

q = 0.26 A s / t (1)

where

q = pump output capacity (gpm)

A = area of cylinder (in2)

s = piston stroke (in)

t = required time for full stroke (s)

- 1 gpm (US) =6.30888x10-5 m3/s = 0.227 m3/h = 0.06309 dm3(litre)/s = 2.228x10-3 ft3/s = 0.1337 ft3/min = 0.8327 gpm (UK)

- 1 in (inch) = 25.4 mm = 2.54 cm = 0.0254 m = 0.08333 ft

- 1 in2 = 6.452 cm2 = 6.452x10-4 m2 = 6.944x10-3 ft2

Hydraulic pump capacity can be estimated in Metric units as

q = 10-6 A s / t (2)

where

q = pump output capacity (l/s)

A = area of cylinder (mm2)

s = piston stroke (mm)

t = required time for full stroke (s)

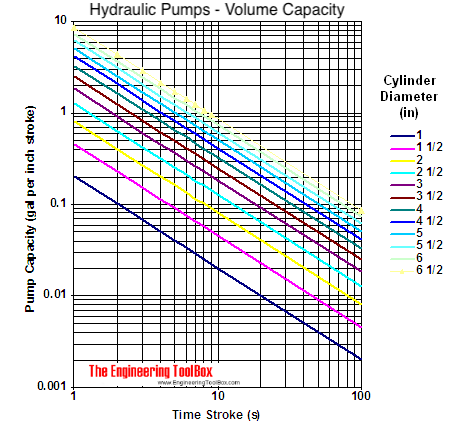

Required pump output for hydraulic cylinders ranging 1 - 6 1/2 inches are indicated below. Multiply pump capacity with stroke length (in).

Example - Required Pump Capacity

A 3" hydraulic cylinder with cylinder area 7.065 in2 makes a 30 inches stroke in 3 seconds. The required pump capacity can be calculated

q = 0.26 (7.065 in2) (30 in) / (3 s)

= 18.4 gpm

Hydraulic Pump Volume Capacity Calculator

Imperial Units

SI Units

Related Topics

-

Hydraulics and Pneumatics

Hydraulic and pneumatic systems - fluids, forces, pumps and pistons.

Related Documents

-

Hydraulic Cylinder Area vs. Diameter

Typical hydraulic cylinders and acting area vs. cylinder diameter. -

Hydraulic Cylinders - Volume Displacement

The volumetric displacement of hydraulic cylinders. -

Hydraulic Force vs. Pressure and Cylinder Size

Calculate hydraulic cylinder force. -

Hydraulic Oil Pump - Horsepower vs. Pressure and Volume Flow

The power required for hydraulic pumping. -

Hydraulic Pump Motor Sizing

Motor size vs. flow rate, shaft torque, shaft power and hydraulic power.