Steam Heating Systems - Design

An introduction to the basic design of steam heating systems.

The simplest steam heating system can installed at relative low costs. The disadvantages with the simple system is the lack of modulating quality.

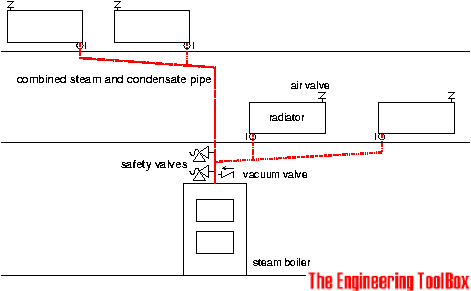

The simplest steam heating system is the

Single Pipe Steam System with Main Pipes Pitched Towards the Boiler

Steam and condensate use the same main pipes. The condensate flows in the opposite direction of the steam.

Air valves are necessary for evacuating air during start-up.

The system is simple but the heat emission from radiators or in heat exchangers is hard to control. Modulating the heat will cause the heating elements to be partly filled with air. The system can work properly in applications where the heat can be modulated directly in the boiler, like applications for warehouses, garages and so on. The system should be avoided where individually modulating of each radiator or heat exchanger is required.

The condensate draines back to the boiler and during stops the system is filled with air. This makes the design suitable for temporarily heated application working under water freezing conditions.

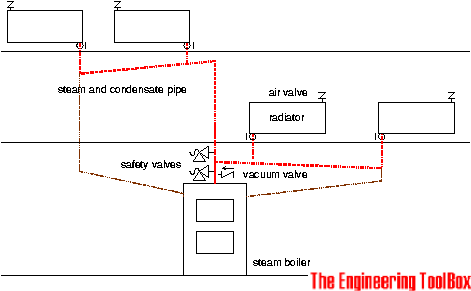

The simple system can be modified to the

Single Pipe Steam System with Main Steam Pipes Pitched Away from the Boiler

This is a better design than the former because the steam and condensate are more separated in different pipes. It can be further improved with the

Single Pipe Steam System with Overhead Steam Distribution

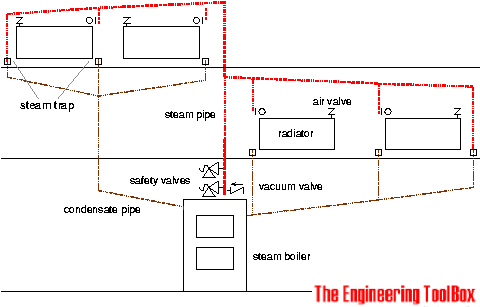

A improvement to this system is to completely separate steam and condensate lines with the

Steam Trap System

With the Steam Trap System steam is hold back in the heating elements and the steam pipes by steam traps. Steam traps may work after thermodynamic or mechanical principles.

The advantage with the system is better individual modulated radiators and heat exchangers.

The disadvantage is more equipment and higher costs.

Related Topics

-

Sizing of Steam and Condensate Pipes

Dimensions of steam and condensate pipe lines. Calculate pressure losses, recommended velocities, capacities and more. -

Steam and Condensate

Design of steam & condensate systems with properties, capacities, sizing of pipe lines, system configuration and more.

Related Documents

-

Heating Water by Injecting Steam

Water can be heated by injecting steam. -

Hot Water Heating System Temperatures vs. Outdoor Temperatures

Hot water heating temperatures adapts to outdoor temperatures. -

Hot Water Heating Systems - Online Design Application

Free online design tool for designing hot water heating systems - metric units. -

Hot Water Heating Systems - Online Design Application, Imperial Units

Online design tool for hot water heating systems. -

Hot Water Heating Systems - Pressure Loss in Steel Pipes

Pressure loss nomogram for hot water steel pipes. -

Hot-Water Heating Systems - Classification

Hot-water heating systems can be classified by temperature and pressure. -

Saturated Steam - Properties - Imperial Units

Steam table with sensible, latent and total heat, and specific volume at different gauge pressures and temperatures. -

Sizing Steam Pipes (lb/h)

Steam is a compressible gas where the capacity of a pipe line depends on the size of the pipe and the steam pressure. -

Steam & Condensate Equations

Steam consumption and condensate generation when heating liquid or gas flows -

Steam - Flow vs. kW Rating

Calculate steam flow rate vs. kW rating. -

Steam Consumption for some Typical Steam Heated Consumers

Steam consumption rates for typical steam heated consumers in industries like bakeries, breweries, paper factories etc. -

Steam Flow Rate vs. Pressure Drop - Schedule 40 Pipe

Flow rate (lb/h) and pressure drop per 100 feet of pipe. -

Steam Heating Air

Calculate steam heated air systems. -

Steam Heating Processes - Load Calculating

Calculating the amount of steam in non-flow batch and continuous flow heating processes. -

Steam Heating Systems - Classifications

Steam systems carries heat through pipes from the boiler to consumers as heat exchangers, process equipment etc. -

Steam Pipes - Online Pressure drop Calculator

Calculate pressure drops in steam distribution pipe lines. -

Steam Pipes - Sizing

Sizing of steam pipe lines - major and minor loss in steam distribution systems. -

Steam Radiators and Convectors - Heating Capacities

Steam radiators and steam convectors - heating capacities and temperature coefficients. -

Steam Trap Selection Guide

Steam trap selection guide - Float & Thermostatic, Inverted Bucket, Bimetal Thermostatic, Impulse and Thermodynamic Disc steam traps. -

Steam Traps - Back Pressure and Capacity

A back pressure in a condensate systems will reduce steam trap capacity -

Steam Traps - Safety Factors

Selection of steam traps and their safety factors. -

Wet Steam - Quality vs. Dryness Fractions

Introduction and definition of steam quality and dryness fraction including calculating wet steam enthalpy and specific volume.