Evaporative Cooling

Evaporative cooling tutorial.

In principle - the basic evaporating cooling system use only water and a blower to cool circulated air.

When warm, dry and unsaturated air is pulled through a water-saturated medium - water evaporates from the medium to vapor in the air. The evaporation energy comes from the air which is cooled down.

- air humidity increase - and air temperature decrease

Evaporation differs from boiling and can be accomplished at a temperature lower than the boiling temperature of water because it occurs at the liquid-vapor interface.

Evaporative cooling can be implemented with

- direct evaporative systems

- indirect evaporative systems

- hybrid systems with indirect and direct evaporative cooling units

Direct Evaporative Cooling Systems

In a direct evaporative cooling system - outside air is pulled through a water-saturated medium (typical cellulose) - or air is sprayed with water - and cooled by evaporation. The cooled air is circulated by a blower.

Moisture can be added to the air stream until saturation.

- dry bulb temperature is reduced

- wet bulb temperature is unchanged

- relative humidity is increased

- specific humidity is increased

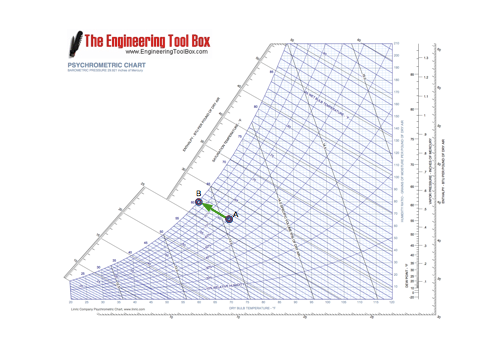

The Direct Evaporative Cooling Process in a Psychrometric Chart

Air at with dry bulb temperature 70 oF and relative moisture 60% (state A) is cooled down (state B) by evaporating water. The process is indicated in the psychrometric chart below.

With 100% humidification of the air - the dry bulb temperature will approach 61 oF.

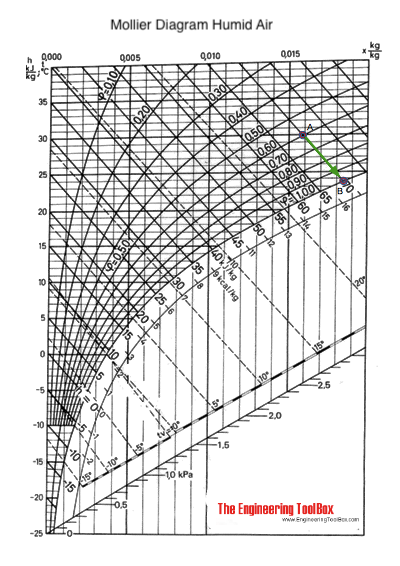

The Direct Evaporative Cooling Process in a Mollier Diagram

Air with dry bulb temperature 30 oC and relative moisture 60% (state A) is cooled down (state B) by evaporating water. The process is indicated in the Mollier diagram below.

With 100% humidification of the air - the dry bulb temperature will approach 23.5 oC.

Indirect Evaporative Cooling Systems

In the indirect evaporative cooling system a secondary air stream is cooled down by evaporating water. The secondary air stream is then used to cool down the primary air in a heat exchanger.

Moisture is not added to the primary air and

- the dry bulb temperature is reduced

- the wet bulb temperature is reduced

- relative humidity is increased

- specific humidity is unchanged

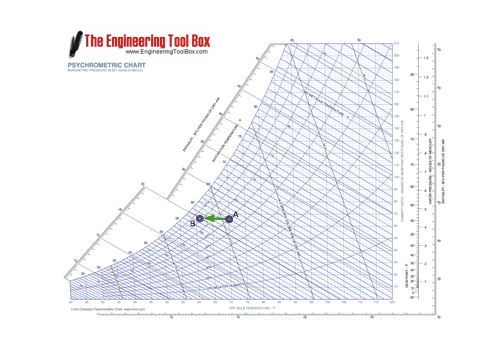

Indirect Evaporative Cooling Process in the Psychrometric Chart

Air at state A with dry bulb temperature 70 oF and relative moisture 60% (state A) is cooled down to state B by a secondary air stream cooled by evaporating of water. The process is indicated in the psychrometric chart below.

With 100% humidification of the secondary air the dry bulb temperature of the primary air approaches 70 oF. The relative humidity of the primary air approaches 83%.

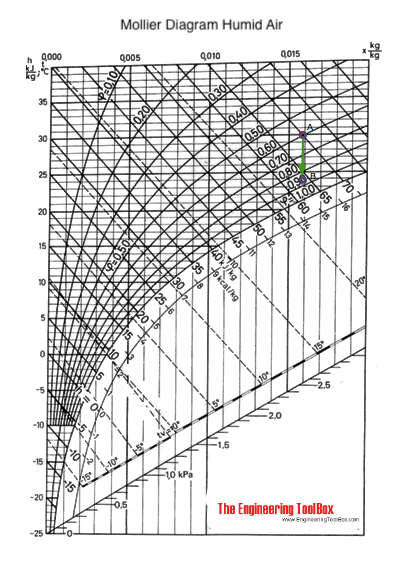

Indirect Evaporative Cooling Process in the Mollier Diagram

Air at state A with dry bulb temperature 30 oC and relative moisture 60% (state A) is cooled down to state B by a secondary air stream cooled by evaporating water. The process is indicated in the Mollier diagram below.

With 100% humidification of the secondary air the dry bulb temperature of the primary air approaches 23.5 oC. The relative humidity of the primary air approaches 86%.

Hybrid Evaporative Cooling Systems

Direct and indirect evaporating cooling units can be combined together in hybrid systems with serial connected indirect and direct evaporative units. In addition evaporation units can be combined with more energy consuming DX (Direct eXpansion) compressor cooling units.

Benefits of Evaporative Cooling Systems

Evaporative cooling systems

- can be economical since the required size of a DX compressor cooling system can be reduced. Evaporation units reduces DX systems run time

- can be more environmentally friendly than a DX system since they don't contain refrigerants

- can be more effective than DX systems at higher temperatures

Note! - be aware that any water system with an operating temperature between 69 oF (20.5 oC) and 122 oF (50 oC) is a potential legionella source.

Related Topics

-

Air Psychrometrics

Moist and humid air calculations. Psychrometric charts and Mollier diagrams. Air-condition systems temperatures, absolute and relative humidities and moisture content in air.

Related Documents

-

Air - Drying Force

The drying force of air depends on the air moisture holding capacity and the water surface to air evaporation capacity. -

Air - Humidity Ratio

The mass of water vapor present in moist air - to the mass of dry air. -

Cooling Tower Efficiency

Maximum cooling tower efficiency is limited by the cooling air wet-bulb temperature. -

Dry Bulb, Wet Bulb and Dew Point Temperatures

Dry Bulb, Wet Bulb and Dew Point temperatures can be used to determine the state of humid air. -

Evaporation from a Water Surface

Evaporation of water from a water surface - like a swimming pool or an open tank - depends on water temperature, air temperature, air humidity and air velocity above the water surface - online calculator. -

Heat Loss from Open Water Tanks

Due to evaporation the heat loss from an open water tank like a swimming pool may be considerable. -

Humidifiers

Sprayed coils, spinning discs and steam humidifiers. -

Legionella

The Legionella Pneumophila bacterium thrives in water supply systems and air conditioning systems - and may cause the Legionnairs disease. -

Liquids - Latent Heat of Evaporation

Latent heat of vaporization for fluids like alcohol, ether, nitrogen, water and more. -

Moist Air - Enthalpy

Sensible and latent heat of moist air. -

Properties of Saturated Steam - SI Units

Saturated Steam Table with steam properties as specific volume, density, specific enthalpy and specific entropy. -

Saturated Steam - Properties - Imperial Units

Steam table with sensible, latent and total heat, and specific volume at different gauge pressures and temperatures. -

Steam and Vapor Enthalpy

Vapor and steam enthalpy, specific enthalpy of saturated liquid, saturated vapor and superheated vapor. -

Water - Saturation Pressure vs. Temperature

Online calculator, figures and tables with water saturation (vapor) pressure at temperatures ranging 0 to 370 °C (32 to 700°F) - in Imperial and SI Units. -

Water - Thermophysical Properties

Thermal properties of water at different temperatures like density, freezing temperature, boiling temperature, latent heat of melting, latent heat of evaporation, critical temperature and more.