Combustion Efficiency and Excess Air

Optimizing boilers efficiency is important to minimize fuel consumption and unwanted excess to the environment.

To ensure complete combustion of the fuel used combustion chambers are supplied with excess air. Excess air increase the amount of oxygen to the combustion and the combustion of fuel.

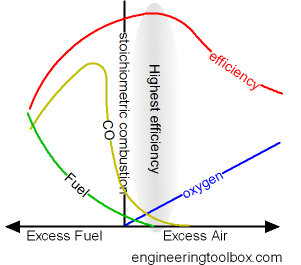

- when fuel and oxygen from the air are in perfect balance - the combustion is said to be stoichiometric

The combustion efficiency increases with increased excess air - until the heat loss in the excess air is larger than the heat provided by more efficient combustion.

Typical excess air to achieve the highest possible efficiency for some common fuels:

- 5 - 10% for natural gas

- 5 - 20% for fuel oil

- 15 - 60% for coal

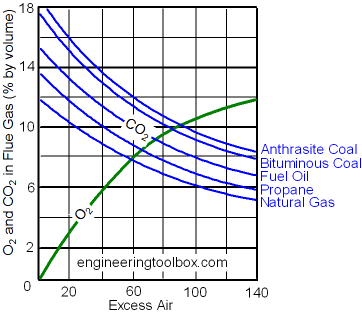

Carbon dioxide - CO2 - is a combustion product and the content of CO2 in a flue gas is an important indication of the combustion efficiency.

Optimal content of carbon dioxide CO2 after combustion is approximately 10% for natural gas and approximately 13% for lighter oils.

Normal combustion efficiency for natural gas at different combinations of excess air and flue gas temperatures are indicated below:

| Excess (%) | Combustion Efficiency (%) | |||||

|---|---|---|---|---|---|---|

| Net Stack Temperature1) (oF) | ||||||

| Air | Oxygen | 200 | 300 | 400 | 500 | 600 |

| 9.5 | 2.0 | 85.4 | 83.1 | 80.8 | 78.4 | 76.0 |

| 15 | 3.0 | 85.2 | 82.8 | 80.4 | 77.9 | 75.4 |

| 28.1 | 5.0 | 84.7 | 82.1 | 79.5 | 76.7 | 74.0 |

| 44.9 | 7.0 | 84.1 | 81.2 | 78.2 | 75.2 | 72.1 |

| 81.6 | 10.0 | 82.8 | 79.3 | 75.6 | 71.9 | 68.2 |

1) "Net stack temperature" is temperature difference between flue gas temperature inside the chimney and room temperature outside the burner.

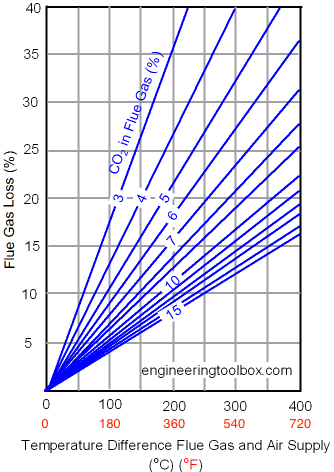

Flue Gas Loss with Oil Combustion

The efficiency loss in the flue gas related to

- temperature difference in flue gas and supply air

- CO2 concentration in the flue gas

with oil combustion is indicated below:

Example - Oil Combustion and Heat Loss in the Flue Gas

If

- the temperature difference between the flue gas leaving a boiler and the ambient supply temperature is 300 oC, and

- the carbon dioxide measured in the flue gas is 10% - then,

from the diagram above

- the flue gas loss can be estimated to approximately 16%.

Related Topics

-

Combustion

Combustion processes and their efficiency. Boiler house and chimney topics. Properties of fuels like oil, gas, coal and wood and more. Safety valves and tanks.

Related Documents

-

Boiler - Efficiency

Combustion gross and net calorific value. -

Boiler Rooms - Sizing

Minimum area in a boiler room. -

Carbon dioxide - Prandtl Number vs. Temperature and Pressure

Figures and table with changes in Prandtl number for carbon dioxide with changes in temperature and pressure. -

Carbon Dioxide - Thermophysical Properties

Chemical, physical and thermal properties of carbon dioxide. Phase diagram included. -

CO2 Calculator - Emissions from Trains

Calculator for CO2 emissions from trains, comparing with alternative forms of transportation (as plane, bus, conventional and electrical cars). -

CO2 Calculator - Emissions from Airplanes

Calculator for CO2 emissions from planes, comparing with alternative forms of transportation (as train, bus, conventional and electrical cars). -

CO2 Calculator - Emissions from Cars

Calculator for CO2 emissions from different kind of cars (gasoline, diesel, LPG, electrical), comparing with alternative forms of transportation (as airplane, bus and train). -

Combustion of Fuels - Carbon Dioxide Emission

Environmental emission of carbon dioxide CO2 when combustion fuels like coal, oil, natural gas, LPG and bio energy. -

Combustion Testing

Combusting testing of fuel oil and gas burners. -

Efficiency

The measure of usefulness. -

Flue Gases - Dew Point Temperatures

Flue gas dew point temperatures and condensation of water vapor. -

Fossil vs. Alternative Fuels - Energy Content

Net (low) and gross (high) energy content in fossil and alternative fuels. -

Fuels Flue Gases - Average Dew Points

Flue gas dew point temperatures for some fuels. -

Heating Fuels - Cost Comparing

Cost comparison formulas for heating fuels like Natural Gas, Propane LP Gas, Fuel Oil and Electricity. -

Intermittent Combustion and Boiler Efficiency

Efficiency reduction due to intermittent boiler operation. -

Oxygen - Thermophysical properties

Chemical, Physical and Thermal Properties of Oxygen - O2. -

Paraffins and Alkanes - Combustion Properties

Properties like heat values, air/fuel ratios, flame speed, flame temperatures, ignition temperatures, flash points and flammability limits.